Dust Collector Remote Switching Design

How To Remotely Switch A Large Dust Collector

Remotely switching a dust collector seems to be a topic with vague answers and very few inexpensive solutions. My new wood shop poses some serious design challenges including the ability to remotely control the dust collector that’s housed one story down below my shop in the garage. After searching high and low for an affordable and effective solution I turned to my electrician for some help and an extremely elegant solution.

The challenge seems quite simple but in reality it sure did pose more questions than solution. How do you remotely turn on and off a 220V motor in a room that’s not within convenient distance to the shop tools?

As I said earlier the Delta 50-763 3HP Dust Collector for my shop is located in the garage while the wood shop is located upstairs in the garage attic.

Possible Solutions

There are several products on the market that can be purchased to control a dust collector remotely. Some of the possible solutions include:

- iVac Pro Switch Wireless Dust Collection Controller-240V 20A

- PSI Woodworking Products LR220-3 220V Long Ranger Dust Collector Switch

- PSI Woodworking LRMSET220 220 Volt Long Ranger Multigate Switch System

There are also more advanced systems that can be installed in the main circuit breaker that will detect current draw from your shop equipment and turn the dust system on. Unfortunately for me, none of the first options worked for my shop because of the 3HP motor and the last system can be quite expensive.

Simple, Flexible Solution

I got pretty frustrated trying to find a solution that would work with my shop. So I decided to pick my electricians brain and ask him for some advice. I’ve worked with him long enough to now he’d likely have a solution and he didn’t disappoint!

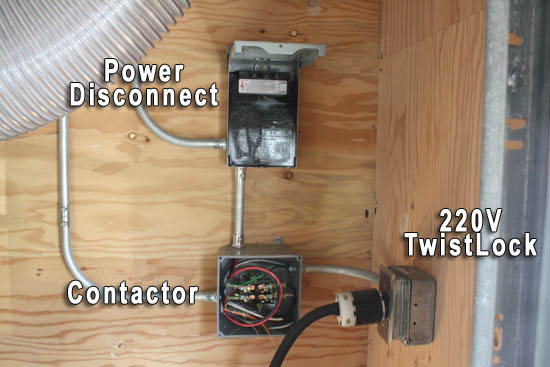

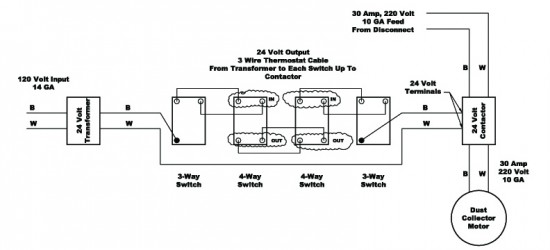

- Power from the circuit breaker is fed to a 30 amp, 220V disconnect located adjacent to the dust collector (see photo below).

- Power is then fed to a small junction box that houses a 220V contactor rated for 30 amps. I’ll talk about this more down below.

- Low voltage (24V) wires from shop switches also enter the junction box and attach to the low voltage leads on the contactor. The 24V circuit is really simple as well. It consists of a 3 wire circuit powered by a 24 volt transformer that runs through 10 switches including two 3-way switches on either end of the circuit and 4-way switches in between. The switches are mounted around the shop adjacent to each work station.

- Power from the junction box is then fed to a 220V twist-lock outlet box which connects directly to the dust collector.

Parts That I Used

- Contactor – The contactor is the key to how this is set up. These are typically used for turning on and off large equipment like air conditioning units so appliance supply houses are a great resource. There are tons of online appliance parts stores that sell these things as well. Amazon is no longer carrying the one I purchased but there is a similar one listed on their site that will work just as well. For this application I needed a 30 amp, 2 pole, 24 volt coil contactor. Obviously your application may be different depending on the size of your dust collector motor.

- Disconnect – I also used a 30 amp pull-out air conditioning disconnect for the main power shut off. You can get one at this link: Eaton Electical / Cutler-Hamm #DPF221RP 30A Pullout Disconnect

- 24 Volt Transformer – I used a 24 Volt transformer with a bit higher volt amp rating that the simple ones you might buy for a door bell. This is necessary to deal with voltage drop over all the switch devices. Honeywell AT140A1042 Universal 24 V 40 VA Transformer

Important Notes

I can’t stress enough that this is a project you really want to involve an electrician on. If you don’t use an electrician to at least consult with you run the risk of damaging your dust collector and even serious injury. It’s also very important that you follow the manufacturers specifications for wire size, breaker size and finally electrical connections.

Performance and Functionality

I suppose one of the fancier systems that turns the dust collection on when you turn your tool on might be pretty cool. But short of that approach I think this one is great. I purposely didn’t want a system that turns on and off by opening/closing the blast gates. That didn’t seem practical to me as there are plenty of times when I might not be moving from my current machine to another so there’s no need to close the blast gate. This system functions flawlessly and I’m 100% satisfied with it.

The total cost for materials on this project was less than $300. That includes the contactor, transformer, disconnect, switches and wiring. This approach can also be used for turning on your air compressor. It’s fairly inexpensive, straight forward technology and something that a confident DIY’er can accomplish with a few pointers from their electrician.

Video Demonstration

Check out a short video that I created where I show you how this works and some thoughts on setting up this remote switching system.