Basement Vapor Barrier For Basement Insulation

Better Basement Insulation Detail

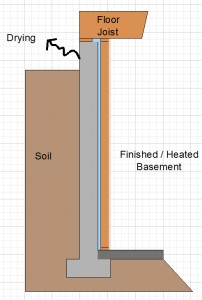

This detail can vary greatly depending on what part of the Country you live in and what R values are required by your local building codes. The idea for this detail is to install a layer of rigid foam board insulation, carefully seal it to create a vapor barrier adjacent to the concrete, then frame a wall and fill the cavities with fiberglass insulation to come up with an R value that meets the design.

- Install a minimum of 1-1/2 inches of rigid foam insulation board. It’s very important that the insulation be installed from the slab all the way up to the top of the wall including the top surface of the exposed concrete wall. If you use a thinner section of foam board you run the risk of it not performing as an effective vapor barrier.

- Carefully seal all the seams in the foam board. You can use a combination of Tyvek Tape, Dow Construction Tape (or similar) and spray foam in a can (Great Stuff for instance). This step is very important in order to create an effective vapor barrier.

- Frame a wall directly in front of the foam board. Typically we like to leave an inch gap to allow for air flow around the studs. Be sure to use a pressure treated bottom plate to prevent decay. We also like to install the PT bottom plate on top of a piece of composite decking material to prevent any wicking of moisture into the framing.

- Install fiberglass insulation in the wall cavities to create a final composite R value that meets the energy code requirements.

- VAPOR BARRIER – The real question ends up being whether or not to install a vapor barrier over the fiberglass and behind the drywall. Typically we are not in favor of a vapor barrier if you’ve installed at least 1-1/2″ of rigid foam (approx. R9). It is possible if you install a thinner layer of foam that the surface of the foam could be cool enough to promote condensation if water vapor moves from the conditioned room and hits the surface of the foam board. For that reason we recommend a vapor barrier if you’ve used less than the 1-1/2″ of foam. This is not a perfect situation and it’s one we recommend you try to avoid.

Bottom Line On Basement Vapor Barriers

The bottom line really is to stop and think about where the water vapor wants to move. If you think about where the water is coming from you should be able to devise a plan that works effectively and avoids the dreaded mold growth. You can also read more about vapor barriers here.

Recent Posts

FloLogic Smart Leak Control Review

FloLogic - Water Leak Detection Every year the insurance industry pays out more than $10…

Building Custom Chess Board

How To Build A Custom Chess Board I first learned how to play chess with…

Grid-Tied PV Solar Systems

Grid-Tied Photovoltaic Solar Systems With the continued increase in electric costs and improved solar panel…

Nest Pro – The Smart Trade

Nest Pro The Smart Trade Every day new technology is changing the world of construction…

Durgin and Crowell Enhance™ Pre-Coated Pine

Enhance™ by Durgin & Crowell We're very fortunate to build homes in an area of…

Building A Paver Patio – Part 2

Building A Paver Patio - Part 2 This article is Part 2 in a series…

View Comments

Hi Todd.

Not sure if you replied but i can't find the page i posted my question on.

I was interested in following your article above on how to insulate the basement and vapor barriers, etc.I noticed how you said frame infront of the foam and to leave a one inch space between for air flow.

How do i help to keep the foam attached to the wall?? I was going to use an adhesive and then frame up against to keep it in place, but the air space you said was better.

Can i use wall anchors for the foam too?? I was concerned if they work on my old basement wall.

Also, my township requires horizontal and vertical fireblocking. How do i incorporate this into your instructions and diagram above and still be in code??

Note: i am not covering or finishing my ceiling. my head height is too low so i will just leave it open and paint instead.

Thanks for all your help.

Rob A.

@ Rob – We typically use an adhesive specifically made for foam board. The key is to put the adhesive on the foam and let it sit for a few mins before you apply to the wall. That allows a skim to form on the glue and it sticks better to the wall. I’m not sure the fire blocking is applicable in your situation. It’s typically applicable with balloon framing which you will not have in this situation. It’s best to check with your building inspector ahead of time and find out what he/she wants. Good luck.

Thanks Todd.

I'll be using the blue foam and adhering the silver side on to the wall and blue side facing into the room, correct??

My township website shows a diagram of the fire blocking on a finished basement wall, and uses horizontal and vertical blocking. it says they require vertical fire blocking at 10ft intervals.

Seems unnecessary to me too, but i'll need to talk to them first and explain what i'll be doing then see what they say.

Thanks,

Rob A.

@ Rob - What foam product are you using? Without knowing which product it's hard to say which face goes towards the concrete.

Hi Todd.

it's the SUPER TUFF-R 1 1/2 In. 4 x 8 Polyisocyanurate Rigid Foam Insulation. it's silver on one side and blue on the other.

Is this the best to use??

@ Rob - You have it correct. The product you are using is probably the top of the line...but certainly will do the job!

the blue side faces? in to the wall?

which product are you using? some of it is blue on both sides.

Hi Todd

I live in southern Missouri, cold but not extreme, I'd like to cover the poured basement walls. I'm thinking about glueing foamboard between 2x2 furring strips and paneling over it. Any reason not to?. I don't think I need the additioanl insulation value a fiberglass-inside 2-4 stud wall would provide. Ceiling is insulated with plastic covered fiberglass and will be covered with drywall. Walls have been uncovered for 15 years so they are as dry as they will be. We use a de-humidifer ithe room. Most of wall area is completely below grade. Also if I can use this set up, do I need a platic vapor barrier under paneling? What type of formaldehyde free foamboard do you redommend? Thanks for your advice. G. Brewer

@ Gary - I would glue the foam board directly to the concrete. Then place your furring over the foam and secure it through the foam into the concrete. Either that or frame a wall in front of the foam. Be sure to tape the seams well. No need for a vapor barrier. Good luck!

todd,

my basement foundations walls were very poorly poured in 1952 w many honeycombs, air pockets, and poor adhesion between poors.when we would get as little as a 1/4 inch of rain i had water running across the floors. for this problem i have installed a complete interior seepage drain system in my basement that also has a lip that sits above the floor against wall that collects any seepage water off walls.i corrected any outdoor water problems-downspouts,improperly sloped concrete,terrain,etc. i have also applied hydraulic cement after chipping out concrete in any spots on walls that still had visible water seepage,i then applied dry lock paint to these areas. this has taken care of any visible moisture on walls or floors after heavy rains--(recently 3")dry is nice. i have also put in a radon mitigation system that is sucking air from under my basement slab through the seepage drain system so any moist air is being removed off of foundation wall(the design was to remove radon but by incorporating it with the seepage system im also pulling air from the moist foundation wall through the earlier mentioned lip against wall). with all this being said i'm currently furring out the walls staying 6" off foundation wall,treated lumber for bottom plate,fiberglass insulation in void between floor joists on sill plate against ribbon joist,below this foam board insulation-to prevent mold- from top of foundation wall 4' down-not the whole stud space- flush with drywall face of stud. does all this sound ok and should i install vapor barrier between foam insulation and drywall. i know this sounds like a lot of information but i figured the more descriptive the better. thank you for your assistance in this matter.

chris

Sounds like you've been busy fixing the real problems which is good! I would recommend you read this article:

http://www.homeconstructionimprovement.com/how-to-insulate-basement-walls/

It shows how I recommend you insulate the basement walls. I really don't recommend only doing 4' as you propose.

I would also recommend you read the following article on the rim joist insulation:

http://www.homeconstructionimprovement.com/rim-joist-insulation-insulating-options/

Good luck.

Reading your article has made me re-think my approach to insulating my basement walls. I live in Upstate NY, where the Winters are brutally cold. My 5-year old house has block basement walls.

I decided to experiment with one wall and installed the DOW 2" rigid foam board, and am building a standard 2x4 wall as well. I intended to fill it with R-13 fiberglass insulation.

One question, however. I am not sure if I should use a faced insulation or not. According to your article, it seems unnecesary (since I am using 2" foam), however I cannot find any rolls of R-13 unfaced fiberglass at the box stores! I can find R-13 pre-cut batts, but they are twice the price and will result in about 6" of waste per batt. Any suggestions? Alternative include (1) using R-19 for 2x6 walls and compressing it (bad), or using R-13 faced rolls.

Many thanks for your insightful article.

-Todd M

@ Todd M - Thanks for visiting the site. The vapor barrier won't do any harm in your situation. If that's the cheapest product available then I say go with it. Good luck.

Hello Todd,

I am having my basement redone after a fire. The basement was previously finished with chip board paneling partially over framing and partially directly on the concrete. We will be using dry wall. The building contractor I am using for the rebuild has framed out the wall with TYVEX behind it. He says that it's not necessary to put in insulation behind the dry wall because the air space and the soil around the foundation will provide all the insulation needed. The basement has never had moisture on any of the walls, but it is always colder in the winter and summer then the rest of the house. Is my contractor correct, or should I insist on insulation on the outside walls of the basement?

Thanks,

Greg M

@ Greg M - First off it partially depends on where you live. However, I would insulate it regardless if it were my home. Secondly, Tyvek will actually allow water vapor to move through it in one direction so technically the water vapor "could" move from the foundation to the framing depending on the side that is towards the framing. Frankly even a "dry" looking foundation was is extremely damp and full of moisture.

Todd great article, just ordered my rigid foam and materials to frame the basement out. I live in Northwestern Indiana and will be finishing my basement as to your article. As an extra form of protection we used Epoxy on all the joints and used Zinsser waterproofing paint LX. We will be using 1 1/2" foam. I am unclear about a few things: How much adhesive should be used per 4x8 sheet of pink foam? Also for the pink foam which side goes towards the concrete?

Lastly we have had a moisture problem on the Rim Joists where air seems to be getting trapped between the Batt Insulation and the Rim Joist creating dampness. Would this work well for the Rim Joist? We are looking for the best solution before we get to the drywall portion of the job. Happy New Year!

@ Alex - Thank for the compliment.

The amount of adhesive really isn't all that important. We typically install a bead every 12" or so. Apply it to the foam, let it stand for 5 mins until it skims over then apply to the wall. Foam board works great on rim joists. Use 2" minimum and seal it in place with spray foam. Good luck.

Todd,

I have glued 2" Foamular 250 to my concrete walls and taped the seams with Tyvek. I have built the 2x4 walls with 1/2" to 1" gap between the studs and foam. My plan is to use the encapsulate fiberglass insulation.(I prefer working with it). Is there a problem in using totally encapsulated fiberglass?

Thanks,

Nick

@ Nick - We've never used it so I can't give an opinion. I think it should work fine after what you've already done. Best of luck.

I have read all of your articles on foam board and vapor movement, but do not understand how the foam board approach solves the problem of trapped vapor. If the foam board is glued tightly to the wall (avoiding the air gap), the water vapor still needs to go somewhere. Why would it not just penetrate the foam board and cause the same problem as insulation? It seems to me that the foam board is as much of a vapor barrier as foil-backed insulation, which everyone agrees is a problem.

Can you help clarify? (I have a below-grade basement (100-year-old house) that is freezing cold in the winter, so I am trying to insulate in some way. I also have some minor seepage that comes through the wall during heavy rains.)

@ Paul - Properly installed foam board insulation can create a very effective vapor barrier. Foam board also has the benefit of not promoting mold growth like fiberglass. There are two issues that you're trying to deal with. First of all the foundation walls are FULL of water and we want to keep that from getting to the framing and wallboard. Secondly we want to keep any moisture from the finished space from passing through the wall and hitting a cold surface where it could condense into liquid form and saturate the framing and wall finishes. Closed cell foam insulation products provide a great barrier to vapor movement. I hope this helps.

Todd,

I have 40 year old pored concrete walls that have never had a water problem in turns of seepage, though have scaled off the original paint job considerably in some areas. Should they be repainted before gluing the foam board to them?

Also, is a combination of foam board and batt insulation the way to go in insulating the areas above the sill plate? I can't tell you how many different opinions I've read on this.

Thanks,

Bob

@ Bob - In both situations it's all about a cost issue. Ideally we'd all insulate basements with spray foam if money were no issue. The idea of using both foam board and fiberglass is a more economical hybrid. Having said that I like to see a minimum of 2" of foam board on the rim joist, spray foamed in place....followed by additional fiberglass to supplement. Best of luck.

I have been searching endlessly and i believe @todd explained this finally for me. Here is what i am doing, I’m sorry if this scenario has been explained somewhere else.

I have a 4 year old house (southern Ontario) it has a delta membrane on the outside foundation... builder has put up R12 fiberglass batts about 4-5 ft down on the concrete wall. I want to install durafoam EPS not XPS directly (PL Premium)against lower half of concrete wall. Tuck tape into existing upper half. Then put dricore down, add metal framing on top. I want to use XPS or EPS directly on the rim joists and seal around with canned spray foam then add roxul insulation behind everything. Then no more vapour barrier just drywall it up.

I know this is not code, but can you foresee there being problems with this hybrid insulation method? thanks

Paul - First off I would never use EPS in a basement, it's an open cell foam and it can/will collect/hold water. Secondly, I would remove the existing fiberglass insulation. You need foam from the top to bottom on the walls.

I am using EPS rigid 2" durafoam with the foil backer (it is a closed cell foam) has an R value of 7.5

http://www.plastifab.com/homeowners/buildinghome/plastispan_duro/plastispan_durofoam.html

Paul,

EPS is NOT a closed cell foam board....it's made with closed cell foam balls...not the same thing.

http://www.homeconstructionimprovement.com/foam-board-insulation-values/

I would NOT recommend that in a basement.

Hi Paul

I was following your post as I need to insulate my basement (block foundation) and was thinking of using Durofoam 1.5 inch (R 5.6), and I was wondering if Durofoam is what you ended up using for your basement. I'm located in the Ottawa, ON area.

Tanya

Tanya - I responded to your email. Durofoam is an XPS foam, which I do not recommend in basements. It consists of closed cell balls of foam that are compressed together, but the "matrix" of balls is not truly closed cell.

Good luck.