Rockwell BladeRunner Review

Rockwell BladeRunner

Specifications

- Voltage: 120V ~ 60Hz

- Amperage: 5.5A

- No-load speed: 800-2800/ min

- Stroke Length: 7z8″

- Table Size: 17″ x 15 3/4″

- Weight: 17.6 lbs

- Cutting Capacity: Wood: 1-1/2″, PVC Pipe 1-1/4″, Aluminum 3/8″, Steel 1/8″, Ceramic 3/8″

Features

- Ready – Quick release wall mount. It’s always ready to cut or you can take it to the job site

- Cut – Change the blade not the tool. Scroll cuts, rip cuts, circle cuts. Cut metal, wood, tile and more.

- Go – Attaches to any shop vac for less cleanup and hassle

Rockwell BladeRunner Review

The Rockwell BladeRunner is an unusual hybrid tool that does some of the the jobs of a table saw and scroll saw. There’s no doubt that this tool won’t replace either of those two tools from most shops but it will certainly be a big asset for some shops.

The Rockwell BladeRunner consists of a sturdy base that sits on rubber feet at the corners. The rubber feet help reduce vibration and noise. The BladeRunner has a 17″ x 15 3/4″ brushed metal table top with built-in T-Shaped slots that hold the miter and rip fence. Once T slot runs from front to back and one runs from side to side.

The motor is mounted below the table so that the blade operates from below much like a jigsaw would work if mounted to a table upside down. The BladeRunner includes an over the top blade guard that easily adjusts for varying material thickness and applications.

Cutting Blades & Performance

Cutting performance is directly related to having the correct blade for the task at hand. We tested the BladeRunner cutting several species of wood and metal including: 1″ thick Cambara, 1″ pine, light gauge aluminum angle, 1/4″ plywood and some PVC trim. We were able to cut all of these materials with ease and control. Aggressive blades really make this tool easy to use, just keep in mind that you’ll need to do finish sanding afterward.

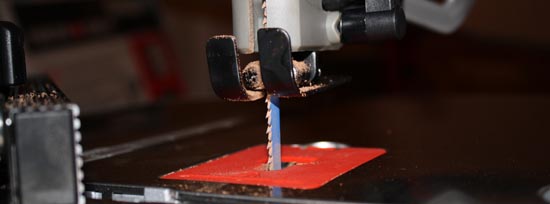

Changing Blades

Changing the blades is very straight forward. As you can see in the photo above the process is very easy. First lift the blade guard up out of the way. Next you simply remove the blade/table cover to expose the blade receptacle. Then simply slide the blade release to the right (you can see in the photo that I have it slid to the right) and remove the blade. The BladeRunner comes with a plastic blade guard you can use to remove the blade but I didn’t think the blades were sharp enough to warrant it’s use. To install a new blade you follow the same process.

Blade Storage

The BladeRunner has a handy storage drawer for storing your blades and the blade removal guard. Blades snap into little holding “fingers” to keep the blades secure. One little improvement I’d like to see is a latch on the drawer. The drawer appears to easily open which might be a problem during transportation of the BladeRunner.

Miter Gauge

The Rockwell BladeRunner comes with an adjustable miter gauge that you can use for cross cutting and it also serves as a fence for ripping materials. The miter gauge fits into the T-Shaped slots on the table. It can be rotated both left and ride from 0 degrees to 60 degrees. The fence can also be adjusted to slide from right to left as well. This miter gauge is a better quality than

Additional Features

The BladeRunner offers several additional features to round out this creative new tool.

Variable Speed Motor

The motor includes a variable speed dial switch for adjusting the blade speed. This is vital for cutting a wide variety of materials from wood to metal. The blade speed can be adjusted from 800 to 2,800 strokes per minute.

Safety On/Off Switch

The Rockwell BladeRunner also comes with a standard paddle on/off switch that also includes a safety key. I really like having these safety keys on my power tools. We have young children and having keys like this is just another way of keeping them safe. I only wish someone would come up with a good system of storing these keys and identifying them so you can store them in a central location.

Miter Gauge Storage

There’s a convenient place to store the miter gauge on the side of the base. With all the built-in storage the BladeRunner is definitely mobile.

Final Thoughts

The Rockwell BladeRunner is a unique new tool that offers the ability to cross cut, rip and scroll cut a wide range of materials including; wood, metal, plastic and even ceramic. While this tool won’t replace a good quality table saw and jigsaw it certainly will help out on a number of projects that require smaller cuts and scroll cuts.

If you’re in the market for a scroll saw and you want something with a few more features then I think you should consider the Rockwell BladeRunner. Once again the quality of Rockwell Tools continues to impress us. In addition they are constantly trying to bring new ideas to the tool market which is really refreshing. The BladeRunner certainly qualifies for one of the more innovative tools that we’ve reviewed over the last year.

Priced under $200 the BladeRunner is a good value. The BladeRunner is available at a number of hardware stores and online. If you’d like to purchase it then I recommend you check out the following link:

- Rockwell RK7321 BladeRunner with Wall Mount, $179.99 with FREE Shipping from Amazon.

Recent Posts

Framing Stick Nailer vs Coil Nailer

Which is Better a Stick Nailer or Coil Nailer? Framers have many choices in nailers…

How Many Roofing Nails Per Square of Shingles

Estimating How Many Nails for a New Roof When it comes to estimating materials for…

Composite / PVC Decking – Layout Tips & Advice

Composite / PVC Decking Layout Tips and Advice Composite and PVC decking have really changed…

Benefits of an ERV System (Energy Recovery Ventilator)

Benefits of ERV Systems (Energy Recovery Ventilator) If you're building a new home or doing…

Vermiculite Attic Insulation Abatement

Vermiculite Attic Insulation If your home was built before 1990 there is a chance it…

Nuisance Tripping of AFCI (Arc Fault) Circuit Breakers

Arc Fault (AFCI) Circuit Breakers Tripping Often An arc-fault circuit interrupter (AFCI) or arc-fault detection…

View Comments

Does the blade guard actually hold the workpiece in place? Does it help keep the blade from deflecting when you make curved cuts? In one of the pictures it looks like there are two rollers that the blade runs through.

My biggest beef with using a jigsaw is that it's hard to cut curves without the cut becoming tapered, not straight up and down. I'm thinking about buying a scroll saw for the times when I can't tolerate this, but I'm wondering if the BladeRunner would solve that.

Benjamen - The guard can be adjusted to rest on top of the work piece. There are a couple of guides on it near the blade but not in constant contact with it. I found this tool to cut curves much better than a jigsaw for one simple reason. You push the work piece through the saw and it's easy to keep the piece perpendicular to the tool. There's a lot less tendency to "push" and distort the blade (if that makes sense).

Hi, I have the older version of this saw and as an “advanced novice” woodworker, I find it a great little saw.

It’s light, easily portable, well designed (except for the lack of a latch on the blade compartment that you mentioned—I lost all my blades during transport once and don’t use it anymore) and perfect for lots of different jobs. Good if you only need a power saw once in a while.

My issue is blade wobble. I find it difficult to make precise cuts because the blade is so jumpy/imprecise.

I always match the blade to the material I’m cutting and the saw can’t have more than 30 minutes on it, so it’s not worn out.

I can make these cuts on other saws, so it’s not my technique. Any way to correct the wobble?

Thanks,

J.