Kreg Jig Review

Kreg Jigs and Kreg Joinery™

The folks at Kreg Tool Company sent us their Kreg Jig to test and evaluate.

Kreg Jig Features

- Removable Drill Guide for benchtop and mobile use

- 1/8” incremental settings for materials from 1/2” to 1-1/2” thick

- Patented three drill guide fixed spacing on the Drill Guide

- Hardened steel drill guides with lifetime warranty

- Includes everything you need to start building

- Doubles as a repair tool

Kreg Jig Specifications

- Body Material: Glass Filled Nylon

- Number of Drill Guides: 3

- Drill Guide Spacings: 9/16″, 7/8″, 1-7/16″

- Clamping Method: Toggle Clamp on Benchtop Base, Face Clamp for Portable Base

- Screw Centering Ability: 1/2″, 5/8″, 3/4″, 7.8″, 1″, 1-1/8″, 1-1/4″, 1-3/8″, 1-1/2″

- Warranty: Lifetime Drill Guide Warranty

Kreg Jig Review

Over the years I’ve seen numerous guys build some really great cabinet face frames and wainscoting with the Kreg Jig system. But I’ll admit that I hadn’t actually tried the system and figured it was probably difficult to master much like trying to use a dovetail jig for the first time!

Well I’m happy to report that using the Kreg Jig System is not only easy to fast! Kreg Jig uses three simple words to describe the process; Drill – Drive – Done! It really is that simple and the results will really blow your mind.

For my evaluation of the Kreg Jig I decided to make a simple face frame. Face frames have always been a complete hassle for me (I only make them occasionally) with all the clamps, extra work space and waiting on glue to dry. My impression of making face frames is completely the opposite now!

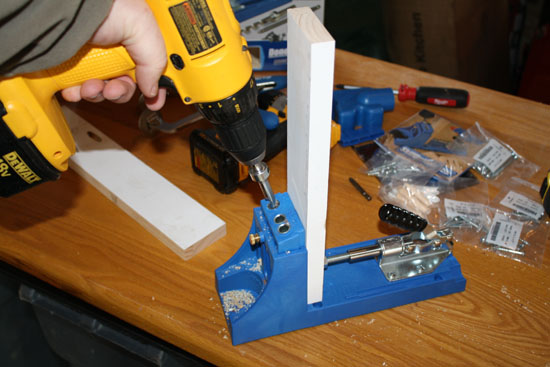

The first step in making a Kreg Pocket Hole is drilling the rail. Above you can see I’m using 3/4″ pine which is set up in the Kreg Jig for drilling. Thanks to easy directions the set-up was very easy. You first adjust the drill bit collar based on the thickness of the wood. There is a easy to use guide for setting the collar built into the jig base. Next the drill guide is set based on the material thickness. Again I set the jig based on 3/4″ thick material.

Once the drill bit collar and drill guide are set you simply clamp the work piece in the jig and then drill the holes.

Pictured above you’ll see the final step which includes clamping the work pieces and installing the Kreg screws in the pocket holes. The key to really tight, strong joints with this system is properly clamping the work pieces. In the photo I’m using the Kreg Clamp which holds the pieces tight and flush while installing the crews.

The kit includes the long square bit for driving the Kreg screws. Another key to the tight joints is using the Kreg Screws which are specifically made for this type of joint. The screws pull the joint really tight and that’s all there is to creating a Kreg Joint.

Final Verdict

The Kreg Jig blew me away in it’s ability to create really strong, really fast pocket hole joints. I knew the system was good from years of testimonies from colleagues but my hands on use only reinforced that impression. The speed of installation is impressive but the actual strength of these joints is amazing. While Kreg claims no glue is needed the addition of glue will make most of these joints nearly indestructible.

Bottom line is the Kreg Jig system is an amazing product that I wish was my idea! It’s easy to use, very effective and a tool that will get tons of use in my shop. From the beginner to the professional this is a tool that I highly recommend!

Where To Buy

Kreg Jigs are sold at all major Box Stores, hardware stores and numerous online stores. There are several different kits available depending on the use. The following are several kits that are available for purchase online at Amazon.

- Kreg K3MS K3 Master Pocket Hole Jig System – $139.00 with FREE Shipping

- Kreg Jig K4 Pocket Hole System – $99.00 with FREE Shipping

- Kreg R3 Jr. Pocket Hole Jig System – $39.95 with FREE Shipping

Recent Posts

Framing Stick Nailer vs Coil Nailer

Which is Better a Stick Nailer or Coil Nailer? Framers have many choices in nailers…

How Many Roofing Nails Per Square of Shingles

Estimating How Many Nails for a New Roof When it comes to estimating materials for…

Composite / PVC Decking – Layout Tips & Advice

Composite / PVC Decking Layout Tips and Advice Composite and PVC decking have really changed…

Benefits of an ERV System (Energy Recovery Ventilator)

Benefits of ERV Systems (Energy Recovery Ventilator) If you're building a new home or doing…

Vermiculite Attic Insulation Abatement

Vermiculite Attic Insulation If your home was built before 1990 there is a chance it…

Nuisance Tripping of AFCI (Arc Fault) Circuit Breakers

Arc Fault (AFCI) Circuit Breakers Tripping Often An arc-fault circuit interrupter (AFCI) or arc-fault detection…

View Comments

My husband and I met the Kreg family at a woodworking show a few years ago. Like you, I was blown away by their demonstration. We promptly purchased a small starter set.

I really like the Kreg Jig too. It's a simple concept but really pays off for applications like building furniture. I've used one to help build some really nice coffee tables and I'd recommend it for any serious woodworker.

I see the Kreg Jig all over the place on US based DIY sites, but have never seen one here in Australia.

I gotta start looking a bit harder.

Thanks for the review Todd.