Flashing A Deck Ledger Board Properly

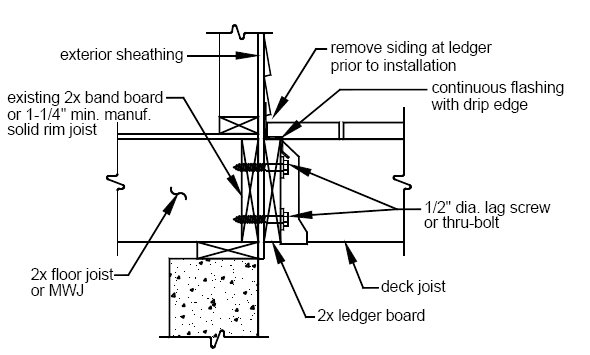

Deck Ledger Board Flashing Detail

Lately I’ve been seeing problematic deck ledger flashing details so I’d like to share with you my perspective on how to properly flash and secure your deck to the house. Properly flashing a deck ledger seems to be a lost skill with most weekend warriors…..let’s discuss how to properly secure the deck ledger and install the flashing.

Building a new deck isn’t really that difficult of a project. However, there are some details that must be followed in order to prevent premature failure of your deck and the area of your house that it’s attached to. The problem with attaching a deck to the house is it creates a great area to collect water. The intersection of the house and deck is extremely vulnerable to moisture problems.

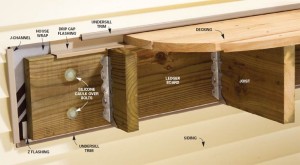

As you can see from the diagram and the photo flashing must be done in layers. The best way to think about it to visualize what a drop of water will do as it hits the deck and moves towards the house. First the rain hits the siding, then it gets to the house wrap, then it hits the drip cap flashing and runs out away from the house.

How To Flash A Deck Ledger Board

First I like to install a layer of self adhering bitchathane (we like Grace Ice and Water) behind the ledger and above it by at least 12 inches. Make sure the bitchathane is behind the house wrap. The house wrap should extend and overlap the bitchathane.

Next mark the location of the bottom of the ledger board and install a small piece of z flashing. When I bolt the ledger board to the house, I like to install 3 or 4 flat washers between the house and the ledger to allow water and moisture to escape and not get trapped. I’d also like to point out that I prefer bolts to lag screws. The reason is lag screws don’t hold very well when then only penetrate and inch or so into the rim joist. Make sure you seal all around the bolt heads with some silicone caulking as another line of defense against water.

Next you’ll want to install a piece of metal drip cap flashing above the ledger board. When you install the floor joists you’ll need to make some small cuts in the flashing to allow the top of the joist to line up with the top of the ledger board. Make sure the house wrap is long enough to cover over the top of the drip cap. (This is a bit different than the photo.) If there is already house wrap on, then cut a slit in the house wrap just above the top of the ledger. That way you can slide the drip cap up under the house wrap. Just remember it’s all about layering.

Finally you can install the decking. The siding above should terminate slightly above the surface of the decking to allow air into the space. Just remember, if water gets into that intersection it’s now going to follow the plane of the drip cap and be pushed out away from the house. If you follow these steps the next time you install a deck you’ll be sure to eliminate a premature failure due to excess moisture and rotting.

Alternate Detail for Masonry Siding

If you have brick siding then you need to use a slightly different approach. Below is a sketch showing a section of the brick wall. The steps are as follows:

- Grind out the grout along a row of bricks.

- Fabricate copper flashing. The flashing has two details worth pointing out. On the end that will fit into the mortar joint bend a very small hem that will act as a wedge. On the lower exposed side bend a standard hem.

- Insert the flashing into the mortar joint so that it fits tightly with the wedge.

- Seal the joint with a high quality flexible caulking.

If you’re planning on building a new deck get yourself the Complete Guide To Decks.

If you want to make your own flashing you can purchase a Tapco 10558 PRO 19 10-Foot-6-Inch Wide by 19-Inch Throat Portable Brake

I am planning on installing a potch roof over my concrete patio. The ledger board will be installed to the second floor joists. The second floor joints are fabricated wood I beams joists. The ledger will be perpediular to the wood I beam joists. The second floor joist wrapper is sheating not 2X. The house is located in PA. What is the recommended method to attach the ledger board to the ends of the I beam joist and joist wrapper(sheething)?

Regards,

Jeff

@ Jeff – Are you really serious that there’s no structural rim joist attached the the I-Joists? Depending on the manufacturer of your joists that may be a rather significant structural issue. I’d look into that with your builder or local building code official or a local engineer. The rim joist provides structural stability for the I-joists and helps transfer vertical loads from the framing above.

As far as attaching a ledger it would depend on if you have access to the I-joists from below. Do you have access? Do you have any photos?

I’m planning a deck above a walkout basement, but I have the same problem. No rim joist on the house to attach to. The ledger will be running perpendicular to the fabricated I joists. I asked a local lumber supplier about it. He knew exactly what I was talking about but only had two options. One, fasten the ledger to the brick (which is against code), or two, put posts/beam near the house and don’t connect to the house. The problem with putting them near the house is the post footings need to go 8ft deep. Any other possible solutions?

Curtis – Can you be more specific about the joist/wall detail? Do the joists just run out to the plywood sheathing? Do you have access to that area? If so you could install blocking/diaphragms between the joists prior to installing the deck ledger. To do that you would have to “pad” out the webs on the I joists and install the blocking/diaphragm with an approved connection that will transfer the load from the ledger into the blocking and into the floor system.

If you make a large enough footing for the locations, they only need to be below the frost line of your area. I am in Baltimore and footings must be 30″ below grade. Typical footing at this depth for a 6X6 post should be 12″ deep, 24X24 but once that is poured with steel reinforcement in it, you need to have rebar to attach to a pour that should go from the footing to 8″ above grade with an anchor bolt embedded in top of pour, this should be twice the cross section of your post, so 12X12 pour. If your home is built with engineering I beams and is an older home, you are required by code to not use the connection to the house for load bearing, hence free standing design must be used. You can attach to the house for stability only and you cannot go over certain heights 9check local code) to an upper floor from any point at grade without angle cross bracing.

There are decent books on decks that cover most of this at Home Depot and Lowes.

Alston Davis

Alston – Thanks for sharing your thoughts. Just curious why you posted on an article about rim joists? Also, your advice only is applicable in your area. In many areas what you have proposed is not relative or true. In our area, we can attach a deck to a house with I-Joists, so long as there is a structural rim board (which we almost always use around here). Also, footing depths are MUCH deeper up here in the North.

If you have access to the joists from below or are willing to cut an access area into a drywall ceiling then the solution may be a DTT2 (Deck Tensioning Tie) from Simpson Strong Tie. As Todd stated, blocking within the web of the I-joist would be needed. This hardware is also helpful for attaching the 4×4 railing posts to rim/end joists. Visit this link for more info. (BTW, I’m not a Simpson salesman! Just a builder happy to share knowledge).

whoops, forgot to post the link…here it is:

http://www.strongtie.com/ftp/fliers/F-DECKCODE13.pdf

Another thing to point out (didn’t see it in the article) is to make sure you don’t nail the deck boards into the band and through the Z flashing, last summer I had to replace all the siding, most of the framing, and detach a second floor wrap around deck because the builder had done this and the flashing failed causing water damaged inside the walls and rotting the entire band as well.

We used a bitchathane membrane behind the rim when we replaced it, was my first time using it.

Also an alternative to the ledger board is using joist hangars instead, some people prefer hangars…

Nice description Todd.

@ Keith – Thanks for that tip. Decks really should have a ledger in addition to the hangers. The hangers shouldn’t be attached directly to the house, mostly due to the fact that there’s not good way to flash the connection. Structurally it’s not a great detail either.

Thanks for all the great info on your site. I plan on adding a small deck this summer. Your technique sounds very good (I just wish I could enlarge the images). My question is how to handle flashing around existing vinyl siding. I will need to cut out the siding to add the ledger board, so what is the best way to extend the flashing up behind the siding without having to remove all the siding from the top down? Also, I have 3/4″ of rigid foam behind my siding. Should I flash from the outer surface of the foam board, or go behind it to the sheathing?

@ Deejay – Thanks for the compliment. First off you’ll want to get yourself a vinyl siding hook that allows you to “unbutton” the siding without taking everything down. This way you can remove the siding up above the ledger board by a couple of courses and install the flashing properly. I would install the flashing behind the foam board directly to the sheathing, then let the foam cover the top of the flashing. Good luck!

I am having a deck installed this summer. The contactor has asked me if I want him to bolt the ledger to the floor joist in the house or into the concrete foundation. He says he can do either one and prefers to go into the concrete foundation because of the stregnth. I have found little research comparing the two methods. Do you know of any studies comparing the two? Which method is stronger?

Julie – The devil is in the details. Either method will work fine when installed properly. The strength comes from the connections so both methods can achieve similar results if installed properly. I would suggest using whichever method leaves the finished deck at an elevation that best suites your needs. I prefer to have the finished deck surface about 6 inches lower than the floor you’re walking out of. This helps with water problems and also eliminates the need for more than one step which could lead to unnecessary trips. Good luck.

Great details Todd, my problem is the deck i have was installed without a flashing, now how do i install one on an exiting deck?

Alex – Depends a bit on what type of siding your house has. Typically it will involve removing some of the siding and some of the decking in order to install the flashing. Then you’ll need to re-install.

Thanks, i checked with a few of my neighbors and all the decks were installed the same way. All the houses have vinyl siding, already had one contractor out to look at the problem, didn’t like the way he described how to repair. Will contact neighbor to see what hes’ going to do. Thanks again

Alex – Best of luck, proper flashing is critical and removing siding is the only way that can properly achieve that.

We are currently building a low profile deck on what seems to be an old deck that was eventually closed in to be part of the house. The flashing on the old part tucks into the siding and lips over the existing floor boards about 1/4″, showing on the outside of the house.

The problem is we don’t know the best options for our new flashing. It can’t tuck up into the siding, the best it can do is tuck into the 1/4″ overhand of the older flashing. Do you have any suggestions.

Thanks in advance,

Jenny

Jennifer – Do you have any photos? If so email them to todd at frontstepsmedia dot com.

Ok, sent photos hope they get to you. Let me know if it doesn’t come through. Thanks again for your help.

Two questions –

1. Any recommendations on flashing up to a log structure? I have a log home with an existing deck which has the deck ledger attached directly to the house rim joist with out flashing or washer spacers for a water gap. My first thought is to remove decking near structure and cut a notch to tuck flash into. Suggestions?

2. Suggestions on flashing for building a new deck to a log home?

Andy – Can’t say as though I’ve flashed a deck on a log home. Couple of thoughts though:

1. Will either deck be on the eave side of the home?

2. My first reaction is to install the ledger with spacers, the hold back the decking. This allows water to get past and not get stuck against the building.

3. Cutting a notch, tucking flashing in, will most likely cause a worse problem as it will be a place for water to get trapped.

Those are just some thoughts that come to mind.

Thank you for the quick reply. Both decks are on eave sides of the home. The new deck is a replacement. When I tore the prior deck off the house I found the builder had put the deck ledger and rim joist together and then ran a bead of ?caulk? along the top of the union. This eventually allowed water to seep between the boards and caused rot, thus the replacement deck. I want to ensure I do not cause the same problem on the new deck. Is there a way to attach a pdf drawing of the way the logs, rim joist and deck ledger come together?

Andy – Any chance you can send me some photos of the existing? send to:

todd at frontstepsmedia dot com

Todd, thanks so much for this fantastic information and your willingness to answer our questions! We have two units in our condo that have suffered damage because of poor or non-existant flashing. We have received a proposal from a contractor to fix these two situations (minus the actual damage caused by the lack of pan). None of us on the condo board know anything about construction so I was wondering if you could take a look and let us know if this quote makes any sense. It seems overly simplistic, but we’re not experts. thanks in advance

Description of Work to be performed:

Install proper flashing to Units 31, 35 and 36 sliding glass door and deck

• Remove the existing interior and exterior sliding door trim

• Remove the existing sliding glass door

• Remove any deck boards restricting the installation of proper deck flashing

• Install a copper door pan and copper deck flashing, copper seams will be soldiered

• Re-install the existing sliding glass door

• Insulate the door surround with low-expanding polyurethane spray foam

• Install new interior and exterior sliding door trim

• Caulk as necessary

Estimated Cost: $1,940 Each Unit

Total Estimated Cost for all three units: $5,820

The estimated cost includes the necessary materials, labor and removal of debris to complete the project listed above.

Excluded from the estimated cost is the necessary painting of the affected areas.

• If an original sliding glass door exists it is recommended that the existing sliding glass door be replaced at the time of this work

Michelle – Seems very reasonable especially considering they are proposing copper flashing.

I have taken bids to replace brick moulding on my back door which has rotted. Also, the band board is rotted under the door. In addition I have been told by at least 2 contractors that the ledger board was not properly flashed on the deck. In order to flash the deck properly, I was told probably at least 2 boards will have to be removed. The deck is Trex (a composite) with 3 3/4″ screws. Today a carpenter in the neighborhood came by and told me it is not necessary to re-flash the deck as the ledger board is treated. I would like to believe that but if it is necessary it seems it would be easier to do it now while the door will be removed.

The owner of the company that built the deck was called back once to flash the deck. At that time he somehow got under the deck and attached some aluminum looking material under the deck. Next another carpenter attached what looks like j channeling along the top of the deck. Help! what do I do now?

If flashed properly does the flashing than cover the bolts or whatever you use to attach the deck to the house?

Donna

Donna – First let me say that the local carpenter is off base and missing the point. Ledger cap flashing ensures that water doesn’t get behind the ledger and rot the band board (rim joist) and then get into the structural framing.

Ultimately the flashing only has to get up behind the siding for several inches and over the top of the ledger and partially down the front edge. Again, this is just to keep water away from the house. The flashing isn’t there to protect the fasteners or ledger.

Good luck.

Todd,

Thanks for your response. I am concerned that the Trex deck is going to be mutilated if the boards are to be taken up to allow the flashing to be done properly. I still have some of the screws that were used to build the deck and they are 3 3/4 in.

On the other hand if not done properly now then what?

So far the band board appears to be rotted just 16 in. between the floor joists.

Donna – It’s likely that the cause of the rot now is the missing flashing. Was the decking top screwed or attached with hidden fasteners? If it was top screwed the damage should be minimal. If not I would still remove it and the worst case is putting some new decking on. This is much better than having your walls/framing continue to rot over time. Wish I had better news.

Todd, I have also received conflicting info on what should be done with the section of band board that has rotted. It is rotted approximately 16 inches between the floor joists and located under the back door. I have been advised to leave it be, the rotting doesn’t matter. I have been told that a section of 2×10 should be cut and nailed in behind the rotted section. I have been told the area should be jacked and the rotted part removed and the new section be nailed in. Do you know who is right? If the rotted is not removed will the band board continue to rot? I do know the ants (and they are just ants) seem to be drawn to rotting wood. It seems to me if it is not sealed it would get worse. Where can I get help?

Donna – The most appropriate repair is to jack it, cut out a section and replace it. That is a very common repair and one that experienced carpenters do quite often. Ultimately it comes down to cost for you. The rotting may continue a bit even after you stop the water problem as the damaged wood will still have quite a bit of moisture. Ants and other insects will indeed be drawn to it.

So far it sounds like you’ve got several inexperienced folks posing as carpenters in your area. Stick with the guy who understands the flashing and rim joist issue.

Living a nightmare now, due to the absence of flashing. Probably for the last 13 years, since the first rain after our house was built, we have been getting rain into the walls of our lower level due to NO flashing installed when our deck was built.

At this time a full wall on the inside has been removed, thus exposing rotten particle board with holes viewable to the siding.

We have, also, discovered the strong possibility that some of our

support joists/beams of our home will have to be replaced. This is

because they were the support the deck ledger, as you call it, was bolted to these house supports.

I bet it would not have taken 2 hours to apply this stuff when they

built the deck. It is so distressing.

Not to mention, last spring we had to repair water damage in our living room due to the absence of FLASHING around the fireplace.

You try to believe contractors know their craft and would do the best they could in order to never hear from you again. And after 13 years, they won’t hear from us again, cuz probably none of them are still working in that field.

So flashing…simple,easy, and sooooo needed.

Todd- Great info. I am about to put a deck on our new house. The deck will be ledgered off the house and 3″ inches below our sliding door. I am looking for info on flashing the ledger which will be attached to Azek trim board that is 12″ wide and then concrete foundation below that( the Azek covers the rim joist and sill by 3″. Inspector says no need to flash but dont want any water getting in the bolt holes. I plan on covering the ledger and Azek with vycor tape and spacing 1/2″ from the house with washers. Should I try to put a rigid drip edge flashing on by cutting a curf in the Azek or just rely on the space to drain water and hope that silicone in the bolt hole holds out water?

Jason – First off why install the ledger over the Azek and not directly to the rim joist? I would remove the Azek, install some self-adhering flashing over the rim joist, up under the siding, install the ledger as you described, install drip cap flashing, then decking. I would NEVER build a deck without flashing that top joint, you will have trouble, guaranteed.

Thanks Todd, when you say the top joint are you reffering to the top of the ledger? Taking the Azek off may not be feasable unless we rip it down to a small strip, but the bottom of the flashing “Z” under the siding and the finished siding is a good 3″ from the top of the deck. I’d hate to have just flashing covering that space. I could take a roll of flashing and go over the vycor and tuck that flasing under the Z flash. At this point I am leaning towards that and not leaving a space between the ledger and covering both surfaces (Azek and ledger) with vycor and then flashing with aluminum roll.

If we have to though the Azek can come down- the inspector didn’t like that though as we would have 3″ to get to siding. I should mention the Azek trim is a transition from the siding above to the cultured stone below- wish we just do this free standing!

Jason – I guess I’m having a hard time visualizing what’s going on. Any photos available? if so you can email them to todd “at” frontstepsmedia “dot” com.

Debbie and I are having the same nightmare. I did write to the contractor who built my Trex deck without flashing. He feels the j channel put on by still another contractor is sufficient and, “it would not be cost effective” for him to flash the deck now. He also said he knows how the deck was built. By the way, the decking is not screwed on it is nailed.

My question now is one contractor feels it is necessary to unbolt the deck from the house, flash between the deck and siding, caulk the bolts and reinstall. Is it necessary to unbolt the deck. It appears the bolts have already damaged the floor joists. Seems it would only make things worse to take them out and put them back.

Donna – Sorry to hear about your troubles. Unfortunately the number of stories like yours is far too great. Any contractor that says a deck ledger doesn’t need to be flashed should get out of the business. Flashing is ESSENTIAL for this situation. J Channel does very little to protect in this case and is frankly only there to hold the siding in place.

Before addressing the siding, the fact that your deck was nailed and not screwed is an indication of poor installation. Decking should never be nailed and that is especially true with composite decking.

I can’t say for sure if your ledger/deck must be un-bolted in order to install the flashing. It depends on exactly how it was done. It may be possible to fix without taking that step. If you had some detailed photos I could better evaluate the situation. The most important piece is having a piece of flashing that is installed up behind the siding (3 inches minimum, 6 inches is better), runs down over the top of the ledger board and under the decking. Depending on which direction your decking runs it can be as easy as removing a piece of decking along the house, removing the lower row or two of siding, installing the flashing and then re-installing the decking and siding.

Todd,

My prior messages described the so called flashing on my deck and the lack of flashing on the sunroom (both added by the same contractor). Today still another contractor prepared for flashing the deck and removing my back door before replacing part of the band board under the door which had rotted to the point that a stick could be put through the band board. When the current carpenter removed the door he discovered the band board is only an inch thick. The house was just completed in Sept. of ’99. He tells me the band board does not meet code plus the deck builder guy put large bolts every 24 inches thru this thin band board. Tomorrow I plan to phone the building inspector for our area. I think they are all sick of me but I am told this lightweight board extends at least all the way down the back of my house and probably all the way around the entire house. Any ideas of what can be done?

Donna – While I agree that a 1″ thick band board (rim joist) is a bit thin I’m not sure the code addresses it. I say this because it’s not really very structural as it’s fully supported typically by the foundation. If it’s a huge concern then additional blocking could be installed between joists up tight to the old band joist.

Todd,

The repairs to my house have not been completed. More damage is continually being uncovered, due to the lack of flashing. I have just re-read your message dated Aug. 16th regarding the repairs needed to the band board. Today my contractor told me he will not be cutting the “worst” section of band board, but rather reinforcing it and then sistering the floor joist. Other sections with less rot will be treated with a type of sealer made for rotted wood and filled with an epoxy like filler. I believe the idea is though the section under the door is rotted, it would still be stronger with the rotted section. I would like your opinion. When I first came upon this it was covered with ants. Seems to me even with a rot repellant type sealer, there still might be an attraction to ants and termites. Would you cut it or support it?

Donna – It really depends on how bad the damage is and if you think the infestation has been taken care of. Leaving rotten wood in place (very wet, full of moisture) and attaching more wood to it will likely result in the moisture being passed to the new. There is no perfect answer. The real key is stopping future water and at a minimum reinforcing the damaged areas.

Todd,

This is my first visit to your site, and I am quite impressed with the detail as well as your quick response to questions, so I figured I would give it a shot.

Like the rest of the posts, I am hoping to replace an existing “martini” deck with a larger version this coming summer. I have designed every last detail of the deck, yet feel the ledger board is still in the gray zone.

The house has two layers of siding. The first (bottom) layer is a masonite siding, covered over by a Hardy Board Cement siding. I had windows replaced on the house last summer, and did some wood rot repair and found there was no wrap on the house on the front bay window! I am guessing this is the same for the entire house.

I am planning on installing a drip cap that extends behind both layers of siding about 4″-6″ (nails allowing). I have seen details with a piece of flashing behind the ledger board and extending over the siding below, in addition to the drip cap. The flashing would be flush with the house and the ledger spaced about 3-4 washers away from the house, with the lag screws passing through the washers. Are either the second piece of flashing, or the washers needed? Also, what can be done to overcome an abundance of nails in the existing siding stopping the flashing from being installed?

Also, I have not been able to find any information on flashing/weather proofing the side (termination) of the ledger board. One side will be on the corner of the house directly adjacent to the vertical trim piece of siding, while the other ends in the middle of the house. Any thoughts?

Thanks for your help.

Mark – Thanks for the nice compliment. It’s nice to see people researching this detail as it’s the most critical long term maintenance issue decks.

Each situation is a bit different and depends on the existing situation. I’m going to assume that you’ll be cutting out the layers of siding behind the ledger (very difficult to create an effective structural connection if you do not). Once the siding is removed you’ll need to protect the rim joist with some sort of flashing, either rolled flashing or some sort of self adhered bitchathane type product.

If you have siding below the deck then having a lower flashing is a VERY good idea. That layer would tuck up behind the rim joist and cover the top edge of siding. There are some folks that like the washers for spacing as it allows things to dry out. I think it’s another good layer of defense but not 100% necessary if you flash things properly.

As far as the corner / end termination it’s hard to say. Sounds like an area that needs a combination of the drip cap and some good caulking. I would use a really good quality paintable silicon.

Good luck!

How to flash a ledger board attached to a brick house?

Joe – There are several ways but the method that I would use would involve using spacer blocks. I would install spacer blocks that are the width of a brick and flash just the spacer block. Then the full ledger gets attached to the spacer blocks.

In order to flash the spacer blocks you’ll need to remove grout with a grinder or dremel type tool. Then use NON aluminum flashing and re-grout or caulk the flashing into the joint.

Good luck.

This ledger is already attached to the brick and is starting to warp and pull away from the wall,there is a 1/4″ gap.

Joe – Sounds like a difficult situation. Flashing for brick is difficult. You really need to embed the flashing in a joint so that water won’t get behind. Do you have a continuous mortar joint that you can cut out and tuck the flashing into?

My house has the plywood-like T1-11 siding with no house wrap (I think). In this case the siding and sheathing are the same thing. My present plan is to use a bitchathane membrane behind the ACQ ledger and stainless steel z-flashing above the ledger. I will be cutting about a foot off of the bottom of the T1-11 to install the flashing. Should the T1-11 be replaced in between the house rim joist and the deck ledger, or be left out? Your expertise is appreciated.

Thanks,

Mike

Mike – I would cut off the old T-111 (12″ piece you mentioned) then replace with a new piece of sheathing (maybe AdvanTech), install the Z flashing up behind old T-111 and over the new sheathing and ledger.

Todd:

Can you show a diagram or photo of how to flash to brick to the ledger. I noticed you talked about adding blocking then attaching the ledger. Could you describe better.

Thanks for your help.

Doug – I don’t have any photos but basically it’s no different than flashing around a chimney. You need to install flashing into the joints and mortar them.

Todd,

I completed the deck I mentioned I was planning in my post last year. It came out great and your guidance on dealing with the siding was very helpful. A couple of things I found:

You mention that you don’t like lags. I did not have inside access to use bolts, but there are some long lags made specifically for this called LedgerLock. They work great. There is a smaller version, called TimberLock, that are terrific for securing 4×4 railing posts. They drive well with a good cordless screw gun and hold tight.

Also, today’s PT lumber is very corrosive to some flashing materials (aluminum for one, and even some grades of glav. steel). I used galvanized steel, but as extra protection, I cut a strip of ice & water shield and laid it on top of the ledger board before the metal flashing to act as a barrier.

DeeJay – Glad to hear your deck went so well. You bring up some great points.

TimberLock and LedgerLock products are really good. We use them all the time and they have become widely popular in the last couple of years. They are especially easy to use with an impact driver.

Using Bitchathane in that case is a great tip as well. Some folks like using poly coated aluminum flashing as well.

Todd,

I need to add flashing to an existing deck which has a ledger board

using lag bolts attached to band board per building code. Problem I am having is that water is getting in behind the ledger board and seeping under the band board. House is old and has no sill plate. The joists and band board rest solely on the foundation wall. The water then rests on top of foundation poured concrete wall and wets the corners of 5 floor joist. Also trickles down the wall inside the basement. Basement is not finished but beginning to. The framing is donw and luckily it rained like crazy yesterday and I was able to watch this leaking in action. Glad it done it now so I can take care of it now. This only does this in a downpour. The house has brick no siding above the decking. So getting flashing behind wrap is a problem. How do you flash the ledger for this situation to stop water getting behind it. Any help would be great.

Thanks, Roger

Brick is more difficult but not impossible. Flashing at brick is the same as step flashing for a chimney. I’ve added a sketch in the article showing you what the detail looks like. Let me know if you have any questions.

Todd,

I did see the sketch. That was close to what I was thinking. What would be good to use to remove/cut the mortar. Would a dremmel work and if so what attachment and or accessories.

Also, have you ever used a general purpose sealer from Henry (Flashmaster) for sealing and or expanding between concrete and wood. They have expandable rubber seals. I used Henry in the past for a leaking problem at mothers home and it worked.

I was wondering if that would work as well between ledger and concrete. What are your thoughts on that?

Thanks,

Roger

Todd,

I came up with even more questions so I am posting them too.

How hard would it be to fabricate the copper flashing?

Also could aluminum or another alternate be used instead?

I live in a safe neighborhood but copper recently has become the new gold. Never know who might try and rip that out if they happen to come across it.

Thanks

Great questions.

1. You really need to use something like copper or lead (and we know that lead isn’t exactly good to have around people especially at deck level). Aluminum will react with the mortar and corrode very quickly. Steel would eventually rust.

2. The flashing isn’t that hard to fabricate if you rent a sheet metal brake from your local rental center.

3. Dremel tool probably won’t have enough power for this job. I’d recommend a right angle grinding tool. We just reviewed a really nice small one on our other site here: http://www.toolboxbuzz.com/brands/porter-cable/porter-cable-small-angle-grinder-review-pc60tctag/

4. Never tried that sealer but it sounds like it might work out.

Good luck.

I have a question about flashing a ledger board. I am putting steps off a raised patio door. There were steps there before I bought the house, but they were done totally wrong. There is a ledger board there that is too short, so I have to extend it. Do I have to put anything behind the Ledger board. I saw on this old house that he put some self adhesive stuff behind the ledger board which created a seal after putting the lag screws into the ledger and through the sill of the house. Then the flashing was installed. How would I install flashing under the patio door which the top of the ledger board sits 2 inches under or is none required there? What and where do you secure the flashing to?

Then I have another door that I’m also reinstalling stairs. The ledger board was attached to the concrete foundation. Do you have to put flashing there as well?

Well your situation is not all that unique. If it was a new door installation I’d install some of that self adhesive flashing behind the ledger board first, then another piece on top of the sub-floor below the door sill and have it lap over the first layer behind the ledger. This helps protect the rough framing if any water gets back there.

In your situation I’d remove the old ledger, then install a layer of self adhesive flashing, then a new ledger. No flashing is required.

Nothing special needed for the concrete location.

Thanks for the advice! So I don’t have to put anything behind the ledger board that is attached to the concrete wall? Is the Grace Water and Ice a good enough flashing for under the patio door? Thanks again for the advice!

My pleasure. Nothing needed over the concrete. Yes Grace is good stuff.

Todd – this is a great site and I appreciate your involvement and answers. It’s obvious you care about helping folks do their improvements properly! Doing it right the first time is important.

I am building a new deck and my question is about properly flashing the deck ledger board and using the ice and water membrane. You’ve talked about this here but I am unclear how to proceed in my situation.

I have torn off 2 rows of siding and below is the Tyvek type membrane. I was planning to install the ledger over the house wrap and then Z flash above the ledger as usal. However, after reading here I am wondering if I should also use the grace type membrane too?

Frankly I hate to cut the house wrap to install the membrane underneath unless it is highly recommended. Also, if I did cut the house wrap I’m unclear on the next steps. Would I then re-tape the wrap (with the ice and water shield below) and then proceed to install the Z flashing over the wrap above the ledger?

Alternatives are to stick with my initial plan with no membrane or, modify my initial plan by using a small width of the Grace type material (about a 4-6 inch wide strip) to seal along the 90 degree corner where the ledger attaches to the house. I could do this underneath the Z flashing, but over the house wrap?

Thanks in advance!

Thanks for the kind words! I’m glad to help out.

Here’s the deal. If it were my home this is what I would do.

Snap a line on the Tyvek at the height of the top edge of your ledger board. Cut the Tyvek on that line and remove it from that line below.

Temporarily lift up the Tyvek enough that you can get an inch or two of the self adhesive flashing BEHIND it. Install the self adhesive flashing from that point down below the ledger board.

Install the ledger board (I recommend using some spacers so the ledger is not ‘tight’ against the house).

Now install the Z flashing over the top of the ledger board, be sure the vertical leg is tucked BEHIND the Tyvek. After nailing the vertical leg I like to use some house wrap tape or self adhesive flashing over that vertical leg (under the house wrap). Now pull the house wrap over the vertical leg and tape it to the Z flashing.

Now you can re-install any siding that was disturbed from above.

That’s what I’d do! Good luck!

If you found this useful I’d sure appreciate it if you’d “LIKE” our Facebook Fan Page here: http://www.facebook.com/homeconstructionimprovement

Hello,

Just tore old deck down which was or floor joists from our house xtended out 11′. Now I don’t have a rim/band joist on house, only blocking between joists. several people told me to lag to banding, but doesnt seem that strong to me. Do you have any suggestions for me to attach joists to house, can I just put the deck joists to bear right next to floor joists over plate on block wall, Thanks

some typos in comment above but in short I dont have a rimboard, so Do I attach new ledger to blocking between existing joists?

Thanks

Wish they wouldnt have built house like this 50 yrs ago

Without a picture it’s hard to say what you have (you could email me photos if you like). Sounds like the first thing you need to do is install sheathing over the cut joist/blocking assembly. Then you’ll need to put on house wrap, self adhesive flashing, blocking, then deck ledger, lagged to the blocking. If you skip the sheathing I agree it won’t be strong enough.

I’m unable to post to the comment area here, (I tried copy and paste)is there an email address I could send a picture or two of my deck project to?

Thanks

send it to: todd ‘at’ frontstepsmedia ‘dot’ com

Thanks for all of your advice Todd, I have learned a lot from your site. We are having a contractor replace our front porch and it appears he hasn’t added any flashing- he was planning to nail the joist hangers into the house, but added a ledger board when he found one rotting spot near the door. I assume even on a covered porch, that flashing is a good idea- especially before the decking is installed? (ounce of prevention?). Also, it is an older house and we planned the boards to be perpendicular to the house (as they were previously)- an 8′ span and purchased 1″x4″ fiberon boards with a pitch of 1/4″ downhill. He has it framed completely level (possibly slight pitch toward house) to run parallel to the house (23′ span with joists 12″ on center). I am concerned about the runoff, staggered decking ends and appearance. Question #1- are my instincts correct? Question #2: Does he need to stop and re-do everything? Question #3- Any advice on communicating with the contractor once he has started? I think I remember an article on selecting a good contractor and I followed the steps (interview, references, talking to the building inspector, at least 3 quotes) and I feel betrayed.

Thanks again for all of your help!!!

Amy and Joe

Amy – I’m sorry to hear about the situation you’re currently in. Let me share some thoughts and hopefully this will help.

1. Flashing is always a good idea even on porches. Porches do get exposed to wind driven rain and snow. Porches need to be washed off and cleaned. These are all good reasons that a quality installation would include flashing.

2. My first question is does your estimate/contract specify the direction of decking? Did you discuss this detail with the builder? If so I’d make him make necessary corrections to support the decking in that direction. Even if it’s framed the other direction he can likely correct that with additional blocking to support the change in direction. The slope is really crucial on older homes that use tight decking especially T&G decking. If you’re using a composite chances are you’ll have a space and water can/will leak through it. So unless you have a really tight decking detail I wouldn’t loose sleep over that.

3. First of all you need to have a frank conversation with him and let him know your concerns. If things are not detailed in writing, stop all work, and get them in writing. Communication is the key here. Be VERY sure you only make payments based on work that is complete and satisfactory.

I hope this helps.

Thank you! He isn’t here yet for today, so your comments are very timely. It isn’t in his written contract, but we have had several conversations (he started a month ago, and we’ve been on his schedule since the end of May). The contract is for pressure treated decking, but we spoke and purchased alternative decking on our own. We had planned tongue and groove ended up purchasing the composite- it has the hidden fasteners, so that was the first verbal change to the contract. During both discussions, we reviewed the perpendicular installation, so that I would purchase enough material. We even specified that the 16′ lengths would be cut in 1/2 to have 8′ lengths.

What is the order of importance? Flashing, direction and slope? The contract is all inclusive, but we purchased the decking figuring that we would figure out if there was any difference in the end (12″ on center vs. 16″ and any other details)

Because of the time lag between conversations, I can see where it would be possible to forget the details. Do you propose that I write something up and ask him to sign it? Also, I have waited at home all morning to talk to him, but he isn’t here yet. I left a message on his cell phone asking his schedule and indicated that I have questions. I have to pick up children soon. Should I leave a note asking him to call my cell?

Thanks again- your support is very helpful.

For the flashing- it seems he would have to remove the ledger and add the weather membrane and flashing? Is that correct? Since flashing was not specified in the contract, would we be responsible for the cost to re-do?

Thanks for the reassurance that there is a way to block it and the slope is not critical with the spacing between boards- still with the previous slope- we rarely had to wash the deck since the runoff was fast. I am sure it will be different with composite.

Just trying to clarify what I need to put into writing.

Thanks again!

Today most modern porches are built with the decking running parallel to the house. This is the most efficient way to frame the porch deck. So the real question is appearance and how you want the deck to look. Without T&G I don’t think the slope is an issue. I think you just need to ask him point blank why the framing is the wrong direction? Did he miss-understand your desire? let him explain his action.

I am building a Pergola that I am planning on attaching one of the 4 side to my house. (8×8 post on the other side) I have a concrete block house and plan to use a Ledger with spacers in between the house (concrete block) and Ledger. Do I need to also add flashing? If so, how would I do that? I do not have Brick like your illustration above.

Ledger will be Cypress…

Thanks!

Is the ledger attaching to the concrete or the house siding?

I live in Florida…

My house is a concrete with stucco. I have no siding, other than stucco. So the Ledger will be connected directly to the concrete wall.

Sounds to me as no flashing is needed. I would highly recommend spacers to keep that ledger from full contact on the stucco.

I thinking of using Hardyboard or some synthetic decking, cut in small pieces, as spacers. Sound like a good idea?

Thank you for all you advice. You are a real pro!

I probably would not do that. Those materials are not ‘structural’. I’d stick with pressure treated wood.

Good luck!

Also…

do I need to treat the Cypress Post (8×8) prior to installing in the ground? I will be installing in concrete on all sides. We have no frost line to think of…

I was considering treating with some sort of wood preservative like Borax

Treating it certainly can’t hurt. However, cypress is known to have good insect and rot resistance. In fact, it ranks higher than cedar which many people use in direct contact with the ground. I’d check with your local lumber yard and get their recommendation.

Lots of good info on your website. We have a bay window in our kitchen. The floor started to rot under the linoleum. My husband tore it out this weekend, and is replacing the wall under the windows and the floor. The flooring under the center bay appears to have been some sort of composit board. There was no flashing under the center window, there was under the two side windows. The floor under there was underlayment. The window is over our deck. We think the deck was built around the window.

He has used ptwood wood to rebuild the wall support and the flooring. He is using concrete wood (backerboard) for the outside of the house under the windows. He has made a small space between the deck and the window, but the support of the windows is on the deck. My question is, should there be flashing, and how do we install it?

There should always be flashing when a horizontal surface meets a vertical surface in order to keep water out. Without pictures/sketches of your situation it’s hard to say what is the best approach.

Todd I really need your advice. I have a contractor that removed an old deck. He uncovered rotted the sections of the rim joist & sill plate (under doors & windows only). There were several colonies of carpenter ants also. The contractor said he didn’t think it was necessary to remove the rotted wood that he assumed didn’t go that far back. However, he never really checked to see how far it went back. There is a small section in the corner where 2 walls meet where the sill plate appears rotted through & chewed by rodents. He didn’t think the sections needed replaced or that the rotten wood should be removed to get down to non-rotted wood. I asked him to chisel out all the rotten wood & he very reluctantly agreed (after a few minutes of arguing). I wanted it removed to prevent the ants coming back & to see how deep the damage went. I went to work assuming he did it. Then I got home & the self healing adhesive flashing was peeling back due to the heat (it was 98 degrees today) & exposed the rotten wood that wasn’t removed like I asked. Now the deck joists are up. Do I tell him to take it all down & remove the rotten wood like I asked or just let him keep building the deck? Should he have replaced the rim or sill plate where it was rotten? How much of the thickness needs to be rotted through to warrent replacing a section?

I hate that I didn’t stay to baby sit this guy. I have no clue what to do & he will be back tomorrow at 7am. Please help!

Holly,

You should definitely ask him to stop all work until this is resolved. I have a strong suspicion this type of work is out of his normal experience. He likely only does decks. Replacing rotted sill plates and damaged structural elements is best left to carpenters with lots of experience.

Frankly if it were me, I’d ask him to stop. Then I’d call a couple of contractors and have them come out to look at the damage. When you call them, ask if they have experience replacing rotted sill plates, rim joists and possibly joists. Many times the damage will get into the floor joists and require additional work.

If this guys gives you a hard time I would be very firm with him. He obviously didn’t do as you asked so now he needs to let you figure out what’s going on.

Leaving that wood in there would be a huge mistake. Now is the time to fix it properly.

I’m sorry you’re dealing with this.

Hi Todd – quick question and thank you for all of your help in the past. I have a contractor who will be installing a concrete patio in the back of my home. The actual concrete patio will be below the foundation sill and only in contact with cinderblocks. Does he have to put a flashing material between the patio and cinderblock? They are both masonary materials. The contractor has told me that he only needs to flash the steps in contact with wood. Thanks!

In this situation you won’t need flashing. In most cases a foam bond breaker will be installed so that there is a clean break between the patio and foundation wall which allows for slight movement.

Good luck.

Thanks Todd – I have a follow on question in regards to another topic – termite damage! After removing the old concrete deck, I found termite damage across 8 ft of sill plates. The damage is bad, very bad and I need to replace the entire sill laying on top of the cinderblock foundation. Termites practically ate through 2 layers of 2 X 6 sill plates. I just concluded an interior renovation, drywall etc. and do not want to lift the home for fear of cracking my double 5/8’s ceilings (they are for sound proofing). Would it be ok if I positioned temporary supports in the basement and removed and replaced one section at a a time? I would like to cut out the sills supporting each floor beam one at a time and then than hammer in the 2×6 sills to support the floor. I look forward to your response.

YOu should be able to support all along it enough so that you can remove and replace without really lifting the house. You just need to go slow and be sure you’ve got enough load into the temp supports.

Thanks Todd – so what you reccomend is that I replace the whole section at once rather than cutting and replacing 20 inches or so at a time?

That’s what I would do.

Hi Todd,

Great website!

I am currently having wood siding taken off of my home and vinyl siding replacing it. We have a deck that is attached to the house through the siding. If there is little to no rotting wood on the siding and the ledger board is not rotted at all is it ok to leave the wood siding up behind the ledger board and simple install flashing. Or should we pull the deck back and take out the wood siding then replace the ledger board and flash properly?

The carpenters will be back tomorrow, hope you are still answering these comments!

Thanks for your help!

Trena

Trena,

Both are viable options. I guess it depends on the condition of the existing situation and how “structurally sound it is”. If everything seems solid and working fine it’s likely going to be ok.

Good luck.

Just reading all the comments I’m amazed at how wrong some builders get the details. Todd, this article is still just as relevant as the day published.

Hi Todd,

Great site and advice, thanks for all the helpful tips for the DIY people!!!

I planned to put new PT decking on my existing deck. What I found is the 2×8 ledger board is attached directly over the 5/8″ vertical grooved plywood siding and into the rim joist. I re-did some of this siding and trim on another side of the house and there is no sheeting below the 5/8 siding, it acts as sheeting and siding. I assume the same to be true on this side of the house as well.

How can I add proper flashing now without removing the ledger board? I don’t think there is damage of the ledger or siding yet, and there is no water getting inside the basement.

My first thought is to use a circular saw and plunge cut right on top of the ledger board into the plywood siding and then use another type of saw to finish the cuts over the joist boards of the deck. Once I have a cut into the siding, now what material to use to properly flash? Galvanized steel would be the easiest to get, but the size wouldn’t be correct, as I would really need to flash over the 2×8 and the layer of 5/8 plywood behind the ledger board. Could I use 14″ vinyl flashing and fold it over to make the bends? 9″ rubber self adhesive is another thought I had.

Other ideas to properly add flashing without removing all the old framework and starting over??

Thanks in advance!

Kevin

Kevin – You’re not far off. What I would do is snap a line about 2″ to 3″ above the top of the joists (horizontal along the length of the ledger). I’d make as straight of a cut 5/8″ deep into the siding. If you can use a track saw or other straight edge I’d recommend that so this cut looks nice. Then I’d make another cut just above the joists (track saw would work very well here or a multisaw. The trick is to be careful not to cut into the studs if you can help it.

Remove that piece of siding. Now you’ve got room to slide in a proper piece of metal cap flashing. They come in varying sizes, most meant to kick out a couple inches (over ledgers, trim, etc), and slide that up behind the siding. The height of that cut (2-3″) depends on what size flashing you can find. Remember, when you put the decking back on, that will come up an inch, plus, the siding shouldn’t be tight on top of the decking, it’s best to leave a gap. The flashing will show, but it’s a much better detail. Make sense?

Hi Todd,

I have a 30′ by 50′ out-building with 12′ 2×6 walls and a metal (tin) roof with T1-11 for siding, currently built. I am attaching an 8′ wide by 50′ office to the length of the building( concrete slabs already poured). The roof will be a pitched 3:12 metal roof using rafters connecting to a 2×8 header board which will be lag bolted into the studs of the 12′ wall.

My question is how would I flash the header board with all the grooves cut into the t1-11 siding and maintain a waterproof and snow proof barrier?

You’ll need to get a piece of flashing up behind the T-111. Usually you’d cut the T-111 an inch or so above where the final roofing would go. You’ll likely need to install that before the roofing, bend it up out of the way, then bend it back down after the roofing. May need to bend a custom piece so it’s large enough. Good luck.

Todd

I live in Southern Alberta. We are rebuilding our deck; builder didn’t use pressure treated lumber or flash the ledger board. My questions are: how to install Z flashing with stucco siding and what will be the correct way to install the bituminous peel & stick if we can’t get behind the stucco? House was built in 1996.

Chris – What type of wood did he use? Without seeing the deck it’s hard to say the best approach. Installing a ledger on stucco after the fact involves cutting back the stucco so the ledger is attached directly to the framing (otherwise it doesn’t meet code). After the stucco and lath are cut, you need to slide a piece of galvanized cap flashing up behind the stucco and lath.

This will be hard to do now that the deck is built, your builder should be responsible.

Sorry, I didn’t describe that correctly. ORIGINAL builder didn’t use treated lumber or flashing. I tore the old deck down and are now about to start from scratch. I understand the importance to attach & seal the ledger correctly but with stucco you have limited options. THis is what I plan to do: cut house wrap [where ledger will go] down the center; install bituminous peel & stick right against the band joist keeping the bottom portion of house wrap UNDER this and a top portion folded over the peel & stick; next slide the flashing under the stucco between the stucco & house wrap; apply a bead of Sikaflex caulking along the bottom edge of the stucco. Do you also need to caulk the edge where the flashing meets the stucco or does this need to be able to drain? Great website and thanks very much.

The key here is to cut the stucco up so that there is a space between the bottom of it, and the finished decking, so air can get in there. It’s best if you can get 2-3″ of flashing up behind the stucco, shouldn’t need to seal that edge. Be sure that new ledger is attached with thru bolts or structural lags. Good luck.

And ledger was attached directly to the band joist…with nails.

Todd, my tahoe cabin’s deck ledger is tacked directly into t1-11 wood siding. My instinct is to replace the deck and eliminate the ledger altogether (add posts near the wall) and leave a big gap between the end board and new flashing tucked under the siding. I would remove the old siding that was behind the existing ledger to about an inch above the deck surface. what do you think?

Lincoln – Ledgers and T-111….sigh! I would cut the T-111 just above the ledger. Install flashing behind the T-111, install new sheathing below that, and install a proper ledger according to code. The flashing should be wide enough so you can slide the ledger up under it. Then I would flash under that and transition back to the T-111. I wouldn’t do just posts, attaching to the house is important in my opinion.

Good luck.

Hello Todd,

I am not sure how old this thread is but thought I would try and get your take. Interesting stories, some horror. My question is attaching a ledger to a house, 2×6 construction, house wrap and T1-11 siding nailed directly to studs. The ledger would be bolted into structural members, i.e. engineered rim board. My thought is to standoff the ledger from the T1-11 using washers as spacers like you pointed out. That would allow water a path of egress between ledger and T1-11. Would this negate the need to cut out a section of the siding, flash, replace siding in cutout area then attach ledger since the siding remains as one continuous sheet?

Ken – T1-11 is definitely a pain when it comes to adding a deck after the fact. I would not recommend this approach. You really need to cut back the sheathing, install the rim joist, and install proper flashing. The washers will trap water at the T1-11 and it will rot sooner than later.

Hi Todd

I’m a contractor and amazed at the stories I’m reading here on your blog about the bad flashing installs, it makes me upset to read these flashing ledger board nightmares. it is an absolute on any project by a builder or contractor to flash all ledger boards and whoever doesn’t should be held accountable financially.

James – I agree!!

Hi Todd,

Just moved into a house where the deck’s ledger board was put directly into the siding with no flashing.

Is it possible to “retrofit” to fix? Can the ledger board be loosened or unattached, trim the siding and slip all the flashing in without dismantling the entire deck?

The siding is vertical board and batten (cedar I think) if that matters.

Thanks

Hi Todd,

Thanks for the detail. How could I accommodate continuous exterior insulation between the deck and the wall?