How To Insulate Basement Walls

How To Insulate Basement Walls

Insulating a basement properly is rather challenging in cold climates. In this article I’d like to discuss how to insulate basement walls in cold climates.

Insulating basement walls in cold climates is a great way to keep your home warmer and drier. However, special care should be used when insulating concrete (or block masonry) basement walls. Below grade concrete foundation walls are very col and damp. If you were to insulate the walls with regular fiberglass batt insulation it is very likely that a mold problem would develop.

Insulating basement walls in cold climates is a great way to keep your home warmer and drier. However, special care should be used when insulating concrete (or block masonry) basement walls. Below grade concrete foundation walls are very col and damp. If you were to insulate the walls with regular fiberglass batt insulation it is very likely that a mold problem would develop.

Recommended Basement Insulation

Therefore I recommend using a combination of products to insulate basement walls. In order to create a vapor barrier and separation between the concrete walls and wood framing I like to use extruded polystyrene insulation (blue board from DOW).

Next we frame a traditional wood stud wall in front of the polystyrene insulation. We do take one special step in framing the wall. First we install a layer of composite decking between the concrete slab and the pressure treated bottom plate of the wall. Finally we install some type of insulation in the wall cavities.

Next we frame a traditional wood stud wall in front of the polystyrene insulation. We do take one special step in framing the wall. First we install a layer of composite decking between the concrete slab and the pressure treated bottom plate of the wall. Finally we install some type of insulation in the wall cavities.

Step 1 – Install Extrude Polystyrene Insulation Boards

The first step in insulating a basement wall is to install the polystyrene insulation (for more information we recommend reading: R Values Of Foam Board Insulation). We like to use a all purpose adhesive that’s approved for Styrofoam products. After the polystyrene insulation is installed each of the joints is taped with construction tape (there are several available from Dow, Tyvek, and other house wrap manufacturers) or some other approved tape that adheres to polystyrene insulation. By taping the joints you are helping keep moisture and cold air from infiltrating into the stud wall cavity.

I recommend you seal the top and bottom of the foam board using spray foam from a can. You can buy products like Great Stuff that will seal those joints very well. Be sure that you install foam board on top of the concrete wall up tight against the wall plate and seal that well.

Want to see how this is done? What the following short video:

One advantage of using closed cell spray foam insulation is that you can avoid having to put the polystyrene and taping it. Simply offset the studs from the wall, and the foam, when applied, will completely seal the wall and insulate it. The moisture drive in a basement is from the interior to the exterior, so the spray foam prevents any condensation or mold growth while providing the highest R-value per inch (>6).

One thing I’d add that if you go with the foam board approach you should either caulk or spray foam a bead along the bottom of the board and the floor to eliminate any air gaps b/t the likely uneven concrete floor and the bottom edge of the boards.

I like the composite decking idea. I am going to use tigerfoam with offset studs as this is a much better air and vapour barrier and will prevent both condensation – from the moisture inside – and evaporation from the wicked water in the concrete walls.

What’s the best way to frame the wall around piping? I have the drainage pipe running along side two walls. I could either bring the wall outabout 10 inches or frame around the piping creating a sort of ledge.

Also, should I consider doing anything with the floor first or can I let it go until I decide what I want to do with it?

Thanks,

@ Hutty – There are two ways to take care of the pipe, either bump out the wall as you suggested or build a soffit around the pipe itself.

Build your walls first then deal with flooring.

Best of luck.

I’ve read a lot of the posts here on using ridged Styrofoam, properly adhered to the concrete/block basement walls, and made hermetically sealed. Let’s say I do all that and I use 2″ thick or better and instead of building and finishing a stud wall in front of the Styofoam, just plaster over it? Or, Drivet? I’m not concerned about “code” police and I agree with the guy who pointed out that below grade spaces maintain heat very well.

What’s your question? yes those are viable options. Not sure why you call them “code police” as many building code officials that I deal with on a daily basis are extremely helpful and very knowledgeable.

Hi Todd,

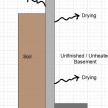

I’m using 2″ wallmate XPS to insulate my basement. It is a recatangular basement of a townhouse with one wall shared with the neighbouring unit. For the shared wall i am using Roxul Safe n Sound just for sound. There is a wall about 8′ from the end of my unit that will divide my basement into a heated and unheated space. Is there any problem with stopping my 2″ XPS halfway along a wall, and then insulating the dividing wall with fibreglass batts? I’m mainly concerned with moisture issues. Is it bad to only have half a wall insulated top to bottom? Also, is it bad if some cold air DOES end up behind my studded wall and contacts the XPS?

Is there any problem with stopping my 2″ XPS halfway along a wall, and then insulating the dividing wall with fibreglass batts? No

Is it bad to only have half a wall insulated top to bottom? I see no reason why you’d want to do that, it simply won’t help much.

Also, is it bad if some cold air DOES end up behind my studded wall and contacts the XPS? No

So just so I’m clear I can adhere the rigid insulation directly to the basement walls and then use a cementitious coating of some sort on the inside? Would a gypsum type product like easy sand work as well or what would you recommend for a coating to use directly on the insulation?

Nathan – I guess you probably could do something like that although I’m not sure what the details might be.

Thanks Todd.

It is hard to tell but I believe in your case your walls are non-load bearing and really just partition walls. In the case of bearing walls would you still use a piece of composite decking under a mudsill? I don’t know the compressive strength of the composite or if there would be other factors to consider in that case.

Thank you.

@ Ian – You are correct. The walls shown are just partition walls. I too would not use this detail for a load bearing wall. I’m only suggesting that this detail be used adjacent to a concrete wall in case of water leakage or excess moisture. For interior partitions or load bearing walls this problem would not be a concern.

I like the theory of the composite decking, but doesn’t it have mold issues. I have Trex on our deck and the areas that don’t get sun get pretty moldy. There must be some cellulose in the composite material. I have to clean the deck with a mold cleaner at least once a year.

I have Trex for our back deck and have to clean the mold off at least once a year in the less sunny areas. Mold might be a concern for use of the use of the composite for this application. I like the idea, and there may be other composites that don’t mold as easily now.

New product out called Azek, solid material versus coated like Trek, will not fade or attract mold, and will not stain with oil products. Its made of solid PVC material, pricy but you never have to do any maintenance for the remainder of your life.

I’m not sure your outdoor mold issue is quite the same. After all, mold even grows on vinyl siding and asphalt shingles on the shady side of homes.

The point of the Trex is to have a product that won’t wick the water up into the wood framing, drywall and insulation.

“Step 3 – Insulate Stud Wall Cavity”

Should this be Faced or Unfaced fiberglass insulation?

==========================

One other thing, I have two of those small (1′ x 3′) windows in a room I’m finishing and I don’t see the need for them. Too small as an emergency exit and I never open them in fear they’ll start leaking if I touch them. I’m also having an egress put in next spring in a different room.

Can I frame over the window or should I replace it with foundation block? (pretty sure I know the answer, but I wanted to see if you had another solution.)

I would use kraft faced insulation in this application, kraft faced against warm side.

We typically trim around those windows so that they can be used if wanted. I don’t see any reason why you can’t block over them if you don’t need them anymore.

How thick is the foam board that is used?

The thickness depends on the R value you want to acheive. I used 3/4″ plus the R11 fiberglass.

Be careful in your choice in foam board; less than 0.75/19.05mm will still allow condensation in extreme cold weather. It is only at 1.00/25.4mm that you begin to see the thermal break you are trying to create.

In my own house I’ve went with 2.00/50.8mm on the walls, and an inch and a half /38.1mm on the floor underneath tongue and groove 0.75/19.05mm plywood sheathing.

We have an increase in temperature retention of almost 7f/5c, makes life real comfortable down there… next addition is a redundant heat source… pellet or wood stove.

The only thing I’m unsure about is the proximity of your wall framing to the closed cell foam board. Some people prepare for any water infiltration “water will get through…” by leaving a half inch space, if only to keep your walls square and true(dry).

We will finish our walls with a big overkill, Roxul Flexibatt R22 RSI 3.87 – For 2×6 studs 24″ on centre for a complete insulation value of R32…

cheers

Before insulating the basement walls, is it necessary or needed to put down some kind of coating such as, Drylock etc. .

A foundation coating is not necessary but it’s certainly one more way to help stop moisture. Good belt and suspenders approach in my opinion.

Todd, Poured concrete walls are not perfectly flat. When gluing the foam board on the concrete walls there will be voids behind the foam board where it doesn’t contour exactly to the wall. Is this a concern for moisture or mold in the void? Or, is the foam board still insulating enough to stop moisture from forming in the voids?

You are correct..the foam will not fit very tight to the wall. The idea is to keep the warm moist air from hitting the cold damp concrete. This is also why i recommend you tape the joints with tape to prevent moisture movement through the foam.

Hi Todd, I have just recently started to plan my basement finishing project and i must say i have already learned a lot from your site. I have one question for you regarding using the polystyrene boards. If i am able to get a hold of 2.5 inch boards (Owens Corning)would i still need to use the fibre glass insulation on top? As this would give me more than the minimum R-12 that is needed in my area of Toronto, Canada. Also if i did go the route of using a little of both, is it necessary to use a vapour barrier on the inside? I am a little confused as some other sites say its not. Any advice would be greatly appreciated.

Using 2.5″ polystyrene would be great! The reason we don’t typically do that is cost. You could certainly skip the fiberglass.

As far as vapor barrier this is a bit of a hybrid approach. With a typical framed wall you want the vapor barrier on the warm side of the framing adjacent to the drywall.

Water vapor can then move towards the outside if necessary in a normal drying cycle. In the basement situation there is no place for the water to go and the concrete is extremely damp. So what we are doing here is sealing off the concrete with the foam and tape. If you don’t do this you will have a serious mold problem in the fiberglass.

Todd, You made a comment that an interior wall treatment,such as DryLoc,was not necessary but won’t hurt. A Basement Insulation Systems report from the Building Science Corporation (2002) states that any impermeable interior wall finish such as vinyl or paint systems should not be used in conjunction with the rigid insulation system. It stops the wall from breathing and allowing the moisture, that may accumulate, to dry. Do you agree or has your experience shown that these types of wall sealants won’t affect the rigid insulation system?

I’m not going to dispute their findings. However, that doesn’t make much sense to me when we’re talking about a concrete basement wall.

Here’s why:

Water actually makes concrete stronger and less permeable over time. (Without going into my graduate research thesis concrete with water in it’s pore structure will continue to cure and hydrate for years, thus making it stronger and more permeable).

So stopping the water from escaping to the house side and drying seems like a good thing to me. Plus we’re trying to stop the moisture from moving towards the house and finished wall.

Just my two cents…

Todd, First I would like thank you for this informative website, it has helped me immensely on determining how to finish my basement walls correctly the first time. Now I need to finalize a floor system. I’ve seen the same 1″ rigid foam, seams taped, covered with 5/8″ T/G plywood, and tap-con’d into the floor. 1.Do you agree with this flooring method? 2.Would you also suggest a sealant coating on the floor before laying the foam board? 3. If small sections of the concrete floor are left exposed, like around the sump pit, water softener system, and furnace, be a problem? As a side note for your readers, my basement research has lead me to a great ceiling system I’m going to use called http://www.ceilinglink.com.

I like flooring systems such as the http://www.dricore.com/en/eIndex.aspx

Never tried the foam board screwed to the slab so I can’t give you my opinion.

Todd, What is the minimum thickness of rigid foam board would I need to use in order to not use fiberglass insulation in my stud walls and still have a comfortable basement?

The minimum thickness depends on local energy codes and the minimum R value you need. Polystyrene has an R value of about 4 per inch. So, if you needed R = 13 let’s say that’s over 3″.

Would Foil backed yellow polyisocyanate insulation work in place of polystyrene insulation? If the answer is yes, would I need to go thicker or thinner to get equal insulation value between the two?

My parents have an unfinished basement in the Chicagoland area. My dad wants to use the Polystyrene on the walls just to get additional insulation. What type of adhesive do you reccomend? Is this ok to just use the insulation and adhesive to the walls?

Ellen

Most hardware stores sell adhesive that works on foam products. You just have to read the labels (this stuff comes in tubes like caulking).

Putting the foam up is a great insulator. However, leaving it exposed is certainly a fire hazard.

Foil backed yellow polyisocyanate insulation is a great choice. It’s typically used in commercial applications for masonry construction. The problem is it’s quite expensive.

The literature suggest that polyiso insulation with foil facing can be almost twice the R value as polystyrene board.

Where I bought my foam boards (T&G pink) didn't sell the sealing tape. So far I've been using "Great Stuff" in the gaps, especially the wider gaps where my cutting wasn't so precise. I will try to find the tape elsewhere, but what about just draping some 6 mil plastic across it?

Also, how important is it that I be perfect in taping all joints/gaps. There were a lot of mechanicals going in and out of my walls I had to work around and it isn't nearly as pretty as the pictures in your post.

Finally, my ceiling height is 7ft, I plan to take 8 ft lengths of fiberglass (I'm doing it exactly as you describe) but tuck the extra foot up into the cavity created by the floor joists up against the exterior (that area is pretty drafty), see any problem with that?

@ Chris – The tape you need is Tyvek tape or similar. That stuff really adheres to foam board well. I think it’s crucial to seal up the joints as well as you can.

Wrapping the additional fiberglass up into the floor joists is certainly a good idea.

I recently framed the basement with 2×4 and insulated using encapsulated R13 between the studs. During the single digit temps and before hanging the drywall I pulled back the insulation to feel how well it was working and noticed iced had formed between the insulation and the block wall. Pulled all down let dry. Reinstalled with a 4mil sheet of plastic installed on the warm side of the insulation. It appeared to seal all up nicely. I noticed the other day water seeping from behind the wall on the floor. I found this site and read about installing the blue board. Question I have is what will stop the moisture build up between the blue board and the block? How is the warm air getting behind the insulation?

@ LJ – The problem is the block wall and/or concrete wall is full of moisture. Concrete walls have a significant amount of water in them for the life is the concrete. Because of this it’s nearly impossible to stop the migration of water from the concrete into fiberglass insulation.

By installing the foam board you’re creating a vapor barrier that will prevent the moisture from getting to your framing, insulation and wall board. You’re also creating the first line of defense for a cold surface toward the heated zone. Again, as warm most air hits a cold surface it will condensate, therefore you’ll still need a vapor barrier on the warm side of the wall.

Will the moisture build up between the blue board and cement block and potentially become a source of mold? As far as installing the blue board just cover the block and not worry about extendine up to the floor and between the joists?

@ LJ – I don’t think this will cause a mold problem. Mold needs some type of food such as paper, wood, etc. to feed off of. Foam board is applied to the outside of foundations all the time and I’ve never seen mold on it.

Question – when using the foam board against the wall,and studs infront and filled with fiberglass insulation, is a vapour barrier still required over the studs/insulation facing the inside of your basement ?

It’s a good idea especially if you only use an inch or two of foam board. If you’re only partially getting he required R value from foam it can still be a cool surface that could let warm moist air condensate on it. So it’s certainly a good idea to use a vapor barrier behind the wall board.

I have read all your postings about wheather or not to use paper faced insulation over the DOW foam boards. I went on the Dow website and they are saying NOT TO USE PAPER FACED INSULATION WHEN USING THEIR TUFF R FOAMBOARDS. Do you agree? thanks, de

Well as I’ve said several times this is an area that’s complicated and you’re likely to get 100 different answers. I’m a bit curious why you want to use the Tuff R product with foil facing? I haven’t used this product in this application so I’d recommend you follow their specifications for installation. However, depending on the thickness you use, it’s likely that the foil faced board will be cool enough to promote moisture condensation if water vapor get’s through the drywall and past the fiberglass insulation.

I will say that some research indicates that well taped and painted drywall can act as a proper vapor barrier.

Thanks for info! I went with the Tuff R 3/4 inch because that is what my lumber company had lead me to use. I went on the Dow web site under http://www.insulateyourhouse and went under insulating basement walls and saw the directions on how to install the walls. If you think I should use the paper faced insulation let me know.

Thanks, De

@De – It’s really a toss up. I’m torn with following their recommendation so that any warranty they might offer will stand (good luck with that) and the mechanics of what will actually happen in the wall. 3/4″ of polyisocyanurate insulation is only about 5. That’s similar to a window so it will most likely still be cool enough to promote condensation. If you were using 2″ of the stuff then I’d agree with their recommendation. Ultimately this is one you’ll have to decide. Best of luck.

I have a poured concrete foundation, and am considering finishing my basement over time. Is it ok to put up the blue foam boards if it will be a little while before i start framing?

I’d check on a few things, first make sure it has an acceptable flame spread based on your local code requirements and secondly make sure it is ok if exposed to sunlight for extended periods. You may have a hard time having it stay up without support in front of it. The adhesive seems to work well for a short period vs longer periods of time.

Great info here! The partition/supporting walls in my basement were built with the house, and extend all the way to the concrete-block walls, so I already have 2x4s studs up against the walls. If I now finish the exterior walls with the blue-polystyrene followed by the wood framing, will I have problems at the joints with the existing walls? And if so, do you have any thoughts on how to deal with those studs?

It’s hard to say how the studs will do. Most likely they will get damp over time and potentially rot and or mold. You might be able to treat them with something before you cover it all up.

recently framed and insulated basement walls in my new home.now have moisture between insulation and concrete.what’s up with that?

How did you insulate the walls?

typar on inside of framing,then roxol R14

now wondering if more insulation is needed in belt? warm air leaking behind wall may be causing condensation to build between concrete and typar?

Unfortunately Typar is not going to keep out the moisture from the concrete. I hate to say it but you’ll need to remove the fiberglass and seal off the concrete with foam.

Thanks Todd.

Thanks for this website-it’s a really great resource. I have two questions:

I read in a Minnesota Department of Commerce publication that it is recommended to install exterior insulation on the foundation before insulating the interior walls. It says this is “necessary to retard air convection within the wall and vapor transport in the concrete masonry block cores.” Do you feel this is necessary? I really don’t want to dig a trench around my entire foundation if I don’t have to! I also have read that this exterior insulation can act as an entry point for termites.

Also, how do you usually test for dryness in a masonry wall before you insulate?

@ Dan – There are lots of publications that promote exterior insulation. However, there are also lots of successful insulation jobs done with only interior insulation. So long as you follow the necessary steps to stop moisture from entering into your finished space you’ll be doing well. That’s why I stress the importance of taping all the seams and NOT placing fiberglass in direct contact with your foundation.

You can easily test for moisture. Tape a piece of plastic to the masonry wall…..be sure to tape it really well. Leave it for a few days, you’ll likely see moisture build up behind the plastic and condensate. This simple test points out the importance of installing some type of foam against the concrete or masonry to seal out the moisture.

Best of luck.

Todd,

My concern with this method is that by still allowing the moisture to condensate behind the foam board, wont there still be a mold issue that you cant see? this would create an air0quality issue correct? and what about at the top of the wall (the floor joists), would you just use the fiberglass insulation in those cavities as well? or cap off the foundation concrete with the foam board and tape the insulate the remaining cavity with the glass insulation? maybe i am just thinking too much about it, but wanted to get your input. BTW, i live in Western NY.

@ Karl – In order for mold to grow it needs water, temperature and a food source, i.e. some type of wood, paper, cellulose, etc. The food source will not be present and therefor no mold will grow. I’ve actually taken down the blue board after a couple years and there’s no sign of mold. You definitely need to install the foam on top of the concrete and seal it very well with foam spray and tape. You’re not over thinking it at all, it’s a very complicated issue that needs careful thought and planning.

My basement walls are only 5 years old and were poured with a form that makes them look like brick and mortar, so the face of the wall is not smooth. I’m worried that the voids between the wall and the blue board could lead to problems. Should I be worried?

Is there any advantage to using steel studs?

Thanks,

Chris,

(From Michigan)

@ Chris – I wouldn’t be concerned with the voids. The real issue here is creating an insulation layer that won’t mold, rot or collect water and also to create a moisture barrier. Not sure about the metal studs, they have their own set of issues in that type of environment. For sure they won’t lead to any mold issues.

I wonder if you have a thought with my daylight basement. Here in GA, the climate does not get sooo cold, but humidity in the basement is an issue in the summer. I use a dehumidifier to take out the water.

Our house is one year old. Our basement is equivalent to 2 walls of poured cement and 2 walls of timber. The house and basement timber walls are wrapped on the exterior with Tyvek. The concrete had tar sprayed on it, and footing area has drainage pipe against it.

The above article will help me with the concrete area.

I was wondering about the wood frame area. It is basically siding, wrap wood sheathing. The ceiling has batting wedged against it, but I was trying to choose insulation between exterior studs. Would interior faced batting be good? I do not want moisture trapped, so I was thinking of perforated craft paper. Looking on google, I have seen gross images of mold in basement conditions. I do not think we would be that bad, but I want to spend wisely once, and not have to undo something in 2 years time.

@ Walter – The traditional wood framed walls should do just fine with any acceptable insulation method. I have a walk-out basement and the wood framed walls are insulated with fiberglass batts. Be sure to use a vapor barrier on the warm side. Best of luck.

I’m getting ready to start the project of gluing the extruded poly foam boards to my cement basement walls. I was hoping to use ENERFOAM by Dow. I would like to use this because it is polyurethane foam adhesive and is available in a straw-applied version. (I don’t own a foam gun). My second choice would be GREAT STUFF PRO, WALLS & FLOORS by Dow, which can only be applied with a foam gun.

Have you had any experience with the ENERFOAM?

I plan on building a 2X4 wall with R13 one inch in front of the rigid foam. I’m still wrestling with the decision between 1 inch or 2 inch board, since I live in lower Michigan I’m leaning towards 2 inch.

Is there a rule of thumb for choosing the preferred thickness of the rigid foam?

Thanks For The Help!

@ Chris – I’m not familiar with Enerfoam. Lots of people actually end up using great stuff foam from a can. From my experience no matter what you use you’ll need to prop up the foam board till the adhesive cures, typically over night. No rule of thumb on the foam, the more the better. 1″ is a minimum, 2″ will work wonderfully and you won’t need as much fiberglass.

Thanks Todd. I thought there were issues found with moisture and vapor barriers. Was that just with batts placed against masonry, and then a vapor barrier trapping in moisture?

For masonry, foam glued, then frame built and batt in cavity if desired, followed by drywall.

For 2×4, batt insulation in cavity with vapor barrier pointing inside, followed by drywall?

I just want to make sure before I start buying.

@ Walter – Most of the problems in basements have been created when people place fiberglass insulation up against raw concrete then install a vapor barrier on the wall site. This creates a ripe environment for mold. What I suggest is either insulate entirely with foam or use a combination.

And on the exterior 2x walls, using batts (interior facing vapor barrier) is not a problem?

@ Walter – Not sure I understand your question. Let me try…

What I’ve done in the past without a problem is to install the foam board, seal it very well, then frame a wall, then insulate that wall with kraft faced fiberglass. There are folks that say it’s not necessary and I think it really doesn’t matter much so long as the foam is at least 1″ thick.

Sorry about that. I have both masonry and 2×4 on the exterior walls. I found all the details for the masonry portion (glued foam, then frame + batts) in the article and follow up posts.

In a previous reply, you mentioned that batts with a warm facing vapor barrier on the exterior 2×4 walls was good. I was just concerned on the 2×4 exteriors if moisture could be trapped in the cavities. I was wondering if you found that or if you had no issues.

@ Walter – No problems there because you’re insulating a framed wall in it’s normal configuration. The only issue then becomes keeping your basement at a good moisture level that’s not too high.

cool – thanks again for the great info and rapid replies!!!

I have a dehumidifier draining to an exterior rain barrel that I use to water the plants (with mosquito dunk inside) I have the humidity set at 45% and I have a fan in the basement (approx 2000 sqft) that helps keep air moving.

@ Walter – Best of luck and be sure to come back again for other home improvement information.

Hello,

What is your reasoning behind the minimum of 1″ rigid foam board, wouldn’t 3/4″ with a framed 2″ by 4″ stud framed wall with fiberglass insulation work the same?

I also have read in many other articles that when utilizing the rigid foam and fiberglass combination, then no moisture barrier should be used because the rigid foam acts as a moisture barrier. If a kraft paper or a moisture barrier is used with the foam board, then you are creating a potential for trouble with a sandwiched moisture barrier zone?

Any input to settle this?

Thank you!!

@ Jonathan – From my research it appears that 1″ is the minimum to achieve a minimal vapor barrier. In fact most research prefers a minimum of 2″ for the preferred solution. 1″ plus fiberglass is an economical solution that offers the best of both products. The vapor barrier on the fiberglass in this situation is certainly a debatable one. There are many references indicating that an additional vapor barrier might be a problem. However, there are an equal amount of references recommended the vapor barrier. I’ve done it both ways with success and never found a moisture problem. The real issue here is to never place fiberglass against concrete.

Hello Todd,

Thank you for your input. I will go with at least 1″ for safe measures.

As far as you are concerned, you think the vapor barrier fiberglass is the safer bet?

Two new thoughts,

First: I was planning on leaving a little space above the floor when I attach the rigid board and fill that space with spary foam to prevent water wicking up into the foam board? That is at least another suggestion I read about. Any thoughts on that one??

Second: I have read about leaving a space between the foam board and the fiberglass insulation, this doesn’t sound right to me but not sure?

Thank you again!

@ Jonathan – The vapor barrier is a toss up.

I don’t believe water will wick up into foam board because it’s a closed cell foam. Sealing the base with foam spray is a good idea though.

Leaving an air space is a good idea in my opinion but not necessary.

Hello Todd

I started putting drylok on my block in the basement.I did not get very far because of weather and 2 children who cant be left alone for more than 5 minutes.So my question is should I even bother with it if im going to put up rigid foam board,

Thank you

@ Nathan – It certainly won’t hurt to use it. Whether it will make much difference is hard to say.

Hello,

We’re in the process of finishing the basement in my parents home. The house was constructed in 2007 and has a poured wall basement. My dad and brother-in-law framed in two rooms and a bathroom this weekend, which I was supposed to help out on, but couldn’t do to a sick little one, which has left me to reading DIY articles all weekend online.

The question is this: They have already framed the rooms with untreated 2x4s directly on the concrete. They haven’t put up blueboard, or any backer behind the wood, and didn’t include a treated sill at the bottom.

Is there anything they could do at this point, short of tearing down what they’ve done to this point, that would provide a sufficient vapor barrier? Can a water sealer be sprayed on the concrete walls? And if so, what type of insulation should be used between the studs, as I’ve read not to let fiberglass insulation touch the concrete.

Thanks for the info.

Nick

@ Nick – Honestly, I’d try to take down those walls. If they shot them to the floor and nailed them to the joists above they should be able to cut them free with a sawzall pretty easily. Then you could easily cut off the bottom plate and replace it with PT. This also would allow you to move the wall forward enough to install a layer of foam board. This small road bump will pay off int he long run and prevent some nasty mold and mildew problems.

I’m not aware of a product that would really fix this current situation.

Best of luck.

Todd,

Thanks for the advice. I passed along the info, which you can imagine how it was received since I’ve been home, not working on it, all weekend.

Thanks again.

Nick

Todd,

Thanks for all the great information on your site.

Have you ever used the Owens Corning pink board, (Foamular 150) instead of the Dow blue board? I’m not sure if there is any difference between the two products, but I can get the pink stuff a few dollars cheaper.

Thanks,

Chris

@ Chris – As far as I know they are the same product. One is Owens Corning and one is Dow. Best of luck!

Thanks for clearing that up for me!

Chris

Here’s a couple of questions – I have an unfinished basement (full concrete walls, but the builder did frame a section to mount the main electric panel. This framed wall (against the concrete) doesn’t allow me enough room to use the poly-styro board between the framing and the wall. However there is enough room to hang a thin sheet of plastic vapor barrier (commonly used on a concrete floor when applying wood flooring) between the framing and the concrete wall. Can I use this thin sheet of plastic barrier to create seperation between the concrete and the framing – and still get away with cutting vertical strips of the poly board to friction fit between the studs? It is just one wall (about 10 ft long) in the same room designated as the furnace room. The remainder of the basement (1600 sq ft) will be completed with the poly-styro board first, then the framing, then the fiberglass.

Second, is there any special attention given when 1″ or 2″ poly board won’t fit behind vertical sewer pipes and concrete walls? Do I butt the poly board directly up to the pipes, or leave an exposed gap? Or, maybe it doesn’t matter.

Thanks in Advance!! I’ve been happy to read many great tips!!

Ryan

@ Ryan –

1. I’d say use the plastic behind those studs, then fill in between with foam board.

2. I’d but the foam up to the pipe and seal it with foam spray.

From what I gathered the moisture problem stems from fiberglass insulation being against the concrete. What if you stud up 2×4 walls agianst concrete but do not insulate and then hang dry wall on the studs? Also can you put padding and carpet directly on top of a concrete floor?

@ Dennis – If you just put up the drywall you haven’t prevented warm moist air from hitting the concrete and condensating. That water will cause mold on the studs and back side of the drywall.

Carpet is installed directly on concrete slabs all the time.

I have a home built in 2001. The builder insulated the top have of the basemant walls with fiberglass insultion (presumably to grade). I want to finish my basement walls correctly. Do I need to tear all this down and add the 1″ polystyrene? Are there any alternatives?

Thanks

@ Tom – If the fiberglass is installed adjacent to concrete I’d say you should definitely remove it. I hate to say it but that fiberglass will do you no favors down the road.

Todd, isn’t this exactly what was done in the video above? I was surprised the fiberglass was put behind the board. What’s the best solution to the framed areq?

Not sure I understand your question. In the video there are two areas of interest that are very different. The area of the concrete walls is insulated with foam board. The walk-out (wood framed) walls are insulated with fiberglass.

I’m sorry, I wasn’t clear. In the video it looks like you put the foam board over the top of the fiberglass batts on top of the pony wall. Is that OK to do? I have the same exact setup in my basement and wasn’t sure if I should pull out the batts and use the foam board instead (for the framed pony wall) or go ahead and put the foam board directly over the top of the unfaced batts which is what it looks like in the video.

Thanks again for posting this. I’ve been researching this for weeks and this is by far and above the most helpful information out there. THANKS!

Colin – I did it in the one location, but the only reason I did so was this basement is so dry. It sits on “beach sand” and there’s very little moisture. In most situations I would not do that.

Good luck.

Todd,

Thanks for the advice. I am refinishing my basement and need some further advice on the walls. I have a poured foundation, but on some walls the concrete walls do not go the full height of the basement. There is 2×6 framing on top of the concrete with fiberglass insulation between the studs. There is plywood on the outside face (I have a full brick house) and presumably the brick is on the other side. As mentioned, the builder insulated this portion of the wall in the basement.

I understand I need to use the 1″ polystyrene against the cement walls but what do I do about the half height walls? What do I do about the upper portion where the insulated studs are?

Thanks

@ Tom – Your situation is not unique. You have “pony” walls sitting on top of short height concrete walls. You basically have two options here and it depends on how you want to finish those walls. Do you want to have a “step” in those walls? or do you want the finish framing to run from floor to ceiling without a step?

Either way you’ll need to install foam on the lower half including the top edge of concrete. Be sure to seal the foam board to the concrete well with foam spray and tape. At this point you can either frame only a low wall up to the top of concrete then step back to the original framing or you can frame a new wall in front of the concrete all the way up to the ceiling.

Leave the original fiberglass insulation in place. Depending on which framing you go with then you can further insulate the upper portion with fiberglass if you frame the wall continuous. Does this make sense?

Thanks for the reply- I had never thought about a “step” wall. I had always planned to build a seperate 2×4 wall from the floor to the ceiling. I will give that some thought as it may add a unique look to the finished result.

Also, I failed to mention that the 2×6 framed insulation portion has un-backed insulation betwen the studs, as well as an additional “blanket” insulation covering the whole wall with a silver aluminum backing. Should I take this down and just leave the insulation between the studs, and if I go with the “step” wall attach wallboard direct to the these studs? what should I do if I go with a continuous wall on theis portion?

Thanks a bunch.

@ Tom – A stepped wall can be quite appealing in certain situations. In fact, some people use it as a focal point to install a flat screen TV above, some use it for built in shelving above or similar ideas.

If you frame a 2×4 wall from floor to ceiling I’d leave all the existing insulation in place. If you’re going to step the wall then you should remove the foil faced, install a vapor barrier (6 mil poly) over the stud cavity insulation, then you can install your drywall directly onto the old studs.

Great…I will probably go the ‘stepped” route. One last question, is the fact I can use the 6 mil poly as a vapor barrer on this portion due to the fact that the outer wall is above grade and plywood and not concrete?

Thanks for all your help.

@ Tom – That’s correct. In your main house there is some type of vapor barrier on the “warm” side of the construction. Typically that is either kraft facing or poly. This keeps moisture from the warm room from migrating towards the cold plywood surface and condensating. The plywood itself is MUCH drier than a concrete wall.

Great- I think I have a plan now. Is it possible to send pictures so you can confirm my installation?

Thanks again.

@ Tom – By all means! Send along some photos and I’ll do an article on how to insulate your basement.

Great! I’ll take someome “before” shots, for your review then perfom the work for some ‘after” shots.

Thanks for helping me do this right.

Hi i’m redoing my basement i’m going to use blue board from DOW my question is which adhesive should i use to install it to the concrete foundation i’ve talked with different people and get different answers. some say even the stuff made for foam board installation eats the board.any suggestions thanks

@ Bob – There are several products you can use. Most hardware stores carry a foam board adhesive in a caulking tube. You can also use “great stuff” in a can. Regardless of what you choose you’ll most likely have to use temporary supports to hold the foam in place until the adhesive cures.

Hi, I’m redoing my basement, and have read an article that uses the foam board on masonry wall, then 2×4 structure and reflective insulation in between studs and wrapped over the studs and drywall. Would you recommend reflective insulation over fiberglass, and would it be ok to skip the foam board since the reflective insulation provides also a moisture barrier? Any suggestions would be greatly appreciated.

@ David – First let me say that you SHOULD NOT skip the foam. All masonry construction today uses masonry, air space, foam, then framing. Are you referring to reflective foil faced fiberglass? Here’s what I recommend:

Masonry – Foam (seams taped) – Framing – Fiberglass – Vapor Barrier – Drywall.

Todd, the reflective insulation that I’m referring to is aluminum foil attached to some sort of backing material or two layers of foil with foam or plastic bubbles in between creating an airspace to reduce convective heat transfer also. The aluminum foil component in reflective insulation will reduce radiant heat transfer by as much as 97%. I’m just afraid of putting fiberglass insulation with a paper vapor barrier because I had some bad experience with this in the basement and mold, of course that basement did not have the foam board.

Hi Todd – a quick question regarding insulating:

The person who framed in the basement here at my home just framed a wall away from the concrete and put drywall over the framing. Now I have a basement that’s always cold in the winter. I want to insulate it, but don’t want to put lots of money into it. I’ve heard that the blow in cellulose is good for this because it fills in the space between the studs as well as the gap between the studs and concrete. What is your opinion? Does this work? I have no desire to pull the drywall off the walls, otherwise the job will become a lot bigger than I can afford. Thanks!

Dan

@ Daniel – Blown in cellulose can be quite effective in this situation. However, you need to talk to the installer and make sure the cellulose has anti-mold inhibitor in it. Some of the cellulose is specifically made to be installed directly against concrete.

Hi Todd,

I have another quick question, one of my walls in the basement is already framed and 3/4″ is the maximum thickness of the foam I can squeeze in between the masonry wall and 2×4 without tearing it apart. My question is, instead of fiberglass with vapor barrier, can I install another layer of foam in between the studs? If so, what kind of thickness would you recommend? If not, what’s the reason behind it?

Thanks a lot,

David

@ David – You certainly can install another layer of foam and frankly that’s a better system. I’d be sure to seal all the foam to the framing with Great Stuff spray foam. The thickness depends on your local code. Most foam boards have R values from 5 and up. So it’s best to go with a value of 5. Assuming you want R11 You’re going to want 2 to 3 inches.

Thanks for the advice!

I’m exhausted researching how to do this exactly. I like what you’ve done the best, so I’ll do exactly what you say. My basement is below grade, block walls, I want to use 3/4 foam unless its gonna cause problems I’ll try and find some 1″. Then frame 2×4 tight against that. Do I really need fiberglass insulation since below grade, and if so would I then put plastic over that on the drywall side? It seems like the plastic would make a nice moldy insulation sandwich. I mentioned your method to a couple people and they were all saying you have to have a gap between the block and the wall for water vapor to escape or something? I appreciate your help.

@ Jake – What part of the country do you live in? The total R value you need will dictate if you need more than the 1″ of foam board. Using fiberglass is a way to keep the cost down. Ideally you’d do it all with foam board. The answer about the plastic really depends on where you live.

sorry i forgot to add that. I live in the southern piedmont of north carolina. thanks again. Walkout basement, finished half completely below grade. Room will be heated.

While I’m here, one more question. Where does the moisture and condensation go once its trapped behind the foam? Thanks

I am curious too about the mold sandwich question that jake asked- installing a vapor barrier after using the foam board and fiberglass.

Thanks

Todd,

With an well insulated basement..do you ever worry about freeze-thaw cycles damaging (i.e. expanding cracks) in the foundation?

@ Steve O – Interesting question. Most modern day concrete contains “air entrainment” (tiny air bubbles) that prevent damage due to freeze-thaw cycles. The only concrete that might be exposed to that would be the outer exposed surfaces. So to answer your question I really don’t think insulating the wall will affect freeze thaw one way or the other.

Most cracking is typically due to shrinkage stresses and or large thermal changes over time. Again, most modern day concrete is reinforced with rebar to account for those forces.

Great question!

Hey thanks

Todd,

My insulation requirement is for a Northern Mich. basement walkout. Walls are concrete block which will have a Dry-Lok waterproofing applied on the block walls first.

I wanted to leave approx. 3/4″ airspace from block wall to 1″ blueboard fastened to back of stud wall. Then I would fill stud cavity with faced fiberglass insul. Should I use a plastic vapor barrier against the block wall first? Other than the airspace and the possible use of visqueen,it would incorporate your system.

Can you comment on the additions/changes that I’ve described?

Thanks for your taking time to analyze the above. Steve

@ Steve – I’d rather see you install the foam up against the wall so you can properly seal all the joints first before framing your wall. The foam will be your vapor barrier. Best of luck.

Hi. Im wading into this and getting confused. I want to insulate my walkout basement. I had a moisture problem from blocked drainage which Ive addressed on the exterior (french drains and some siding where possible.) For the inside, I hear two main options:

1- Masonry – hard foam (seams taped) – Framing – Fiberglass – Vapor Barrier – Drywall.

2- spray foam on the concrete plus framing and drywall.

option 2 has the advantage that it seals up the irregular space in the floor joists but may be cost prohibitive. Other than this, do you favor one over the other?

Other questions:

If option 1, I also hear about blowing a fan behind the studs to move the air. What do you think of that?

If option 2, do you use a moisture barrier in addition to the spray foam?

Regarding moisture barrier:

a) Do you recommend against drylock?

b) what about the micro space between wall and hard insulation or between wall and spray foam insulation?

Are there any methods that would conserve more living space?

I was thinking of using metal studs to prevent mold from possibly getting onto wood studs. Do you like this?

If you go to all this trouble to protect walls from forming moisture by having warm air meet cold in a dark stagnant space, what happens on the floors??

Is there more to consider?

thanks very much.

@ Chris – You’ve asked a ton of questions but I hope to give you some basic responses. It really comes down to money, option #1 costs less but option #2 works better. In both cases the foam creates the vapor barrier to prevent moisture from getting to your framing materials. I think metal studs and wood studs are a wash. There’s very little you can do to minimize the few inches that it takes to do this correctly.

Yes, I can confirm that if you were to insulate the walls with regular fiberglass batt insulation it is very likely that a mold problem would develop in the basement.

I like this combined approach, and would suggest for anyone starting a basement finishing.

How can I reach you via email to send pictures of my basement situation (interior waterproofing with gap between wall and floor?)

I used the email link in your “about” section and I am not sure you are getting the mail.

Thank you for your time

Todd,

I have a question regarding your wall system for basements. I plan to finish mine. In certain portions of the basement I will have to create a closet or rather deep air space (6-12″) to accomondate plumbing. One wall has many plumbing drains routed on it. Another area has the well pump. My question is, how best to attach the foam board in these situations to the concrete? Can I avoid doubling up on 1x & sheet rock? Without pictures tough to describe but maybe this helps.

#1 concrete + Foam + 6″ air + 2×4 + sheet rock = nice long wall

#2 concrete + Foam + 24″ air + 2×4 + sheet rock = well pump closet.

I live in CT, so hoping foam with R3-4 will be enough and avoid fiber glass and vapor barrier?

Thanks,

Todd

@ Todd – Couple of thoughts. Even in CT I think you’ll be far short of the recommended/required insulation values for a finished space. The latest Energy Codes are fairly aggressive and require a decent amount of insulation. I would recommend you install at least 2″ thick foam at a very minimum if you’re not going to install the fiberglass. Be sure that your well tank closet does not get too cold. The air spaces are a good thing!

My thoughts as well Todd, I will plan to add Fiber as well.

Given I have areas where 2×4 wall won’t be against foam board. What’s the best method to attach to the concrete? Powder nailer?

Thanks,

Todd

@ Todd – I would only fasten it at the bottom and top. Use Powder actuated nailer at the bottom and screw or nail the top plate to the floor above.

Hi Todd-

I’m looking to finish the basement of a house I purchased 3 years ago. It is in Minnesota and is 15 years old. The basement foundation is concrete block. The builder framed the walls, but the studs are against the concrete block. Currently there is roll insulation between the studs. What is going to be the best solution without breaking the bank? Any advice is greatly appreciated. Thanks for your help!

@ Ryan – Are the walls sheathed already? If not then I would “cut” them free at the bottom and top plate, move them away from the wall far enough to install foam. Make sense?

After you put up the vertical XPS board, do you also put the foam board on top of the blocks to meet the sill plate?

How do I install a fireblock to meet code? Can you recommend any articles on this?

Thanks.

@ Sam – You are correct, foam should be installed on top of the concrete or block up to the sill plate.

As far as the fire block goes, can you be more specific? Not sure if a fire block is required between the concrete wall and floor above.

Sorry but the more I read the more confused I get. The foam board does or does not touch the floor. If it does not then does it set on the composite or the treated sill plate? The only composite I can find in the area is a 1×4 or actual decking. Can I use the 1×4? I was going to use this under the treated wood but if the water would ever go over the composite wouldn’t I have the same problem as just using the treated wood for both layers of the sill plate? Don’t understand why you don’t recommend composite for both layers of sill… Any wood with retain the moisture correct? I also see you have blue board: can the white board be used, since I was told the only difference is in the production process. For my area here in Michigan I was going to use 1” or 1.5” foam board and maybe r-11 in the walls but this seems redundant as most of the cold will still come up from the floor.

Thanks in advance.

@ Rob – I run the foam down to the floor. Then we rip the 1×4 decking down to the width of the wall framing. The decking and wall framing all go up against the foam. The composite decking just keeps minimal moisture from wicking up into the framing. If you actually get more than 3/4 of an inch of water you’ll have other problems to deal with. White foam and “blue or pink” foam are definitely not the same.

Check out: http://www.homeconstructionimprovement.com/foam-board-insulation-values/

I live in the Seattle area. We’ve done a remodel on our house and I have put insulation in my basement ceiling. My main concern in keeping the upstairs warm and doing what I can in the basement to help with that. My basement walls are 1/2 concrete foundation and the other above it framed wall. I don’t really want to take away from the size of my basement by framing another wall. Will it help me much to simply put insulation board on the existing wall?

@ John – There are two issues. 1 is how much will it help and the 2nd is whether your local building code requires it. If you’re really worried about losing space then I would consider applying the foam board and then using 1×3 strapping, shot directly into the concrete. This would limit the thickness to under 3 inches. I really do think it helps significantly to insulate the concrete. Concrete is damp and cool year round.

Thanks Todd-

Building code isn’t an issue. I’ve already received my final as it is. Are you saying that I should put the strapping on the concrete with insulation board over the top of that. The framing and sheathing above the foundation wall is pretty close to being even on the inside with the concrete. I’m planning on just using the insulation board as my finished surface and putting storage shelving over the top of that. What’s the best type of board to use? Is it best to use the stuff with the foil face? I’m thinking of using the board on my basement ceiling as well which already has insulation between the floor joists. Is that a good idea?

@ John – What I meant was install the foam first, then attach the 1×3 strapping over it so it holds the foam in place. This also gives you something to attach things to after. Foil faced Polyiso is really good. If you’re not going to cover the wall then I really recommend you use the foil faced. The ceiling would work well also.

Thanks Todd-

Can you use an adhesive to put the board on with or screw it on in the area I have wood underneath? Is there a particular thickness I should use?

I live in southwestern Ohio and was wanting to know if it is necessary to insulate the full height of the basement walls? I’m refinishing my basement and planned on putting 3/4″ foam on then studding out my walls. Do I need to put fiberglass insulation all the way down the wall or can I just go below the frost line?

Thanks,

Steve

@ Steve – You definitely should insulate all the way to the bottom. I’d also recommend that you use at least 1 inch minimum thickness foam to ensure a good vapor barrier.

Todd,

Should I insulate my concrete floor as well? How much heat is lost through the floor versus the foundation walls?

@ Rich – That really depends on whether your slab was insulated underneath or not. If it wasn’t insulated then you may want to consider insulating the slab and placing a sub-floor over that.

Todd, as a vapor barrier goes, wouldn’t 4mil visqueen work as well, if not better than the foam board?

@ Steve – Not sure as I’ve not used that product before. Anyone else care to comment?

Todd, great website. I have a concrete block basement that I am about to finish. Ere are weep holes low on the walls, near the interior french drain system. After a thaw or heavy rain, water drizzles out of some of weep holes, and there can also be damp spots on some blocks from pressure pushing water through the pores.

The idea of 2″ xps foam sealed to the block wall addresses my moisture concerns related to condensation, but I am still fuzzy on if it addresses hydraulic pressure related dampness/moisture concerns. I am picturing pressure would build up in the block wall and any water would trickle out the pores (and weep holes) and down between the block and xps, and land in the french drain.

My question is this – should I seal the 2″ xps right tight to the wall all the way down and seal it tight to the floor, right over the weep holes? Or should I keep the xps an inch shorter, and seal it to the wall just above the weep holes – leaving them exposed?

Thanks!

You can’t possibly seal the XPS tight enough to stop the water. Having said that, the water will find it’s way to the drain. I’d go ahead and install directly over the wall and holes.

Good luck.

Todd,

On insulating the floor: Would something that has an R value of around 3.2 be enough?

@ Rich – That would certainly help. Plus if you build a sub-floor that’s going to improve the situation as well.

Rich,

Check out http://www.ovrx.com. They have a tile subfloor system that combines 3/4 inch XPS foam board with 3/8 inch T&G OSB board. This is what I’ll be using on my floor.

Jeff Mazey

Todd,

Ilive in northern Ohio and I am partitioning off a room in our basement. Two of the room’s walls will be against the poured concrete basement walls. Due to space limitations I have to use one and a half inch thick Dow blue board instead of 2 inch. I do not plan on using composite decking under the sill plate but I am using pressure treated lumber for the sill plate. Is this a total major mistake? When I am ready to install the fiberglass insulation do I use kraft faced or unfaced fiberglass insulation between the studs?

Thanks,

Dennis

@ Dennis – The composite decking is just an improvement over PT. It helps prevent wicking of moisture from the concrete slab up into the framing. So it’s certainly not a game ender! The question about faced or unfaced is debatable and really depends on how damp your basement is. If you read previous comments and responses you’ll get an idea of what I mean. If you do use kraft faced, be sure you seal the foam VERY well and be sure you basement is on the drier side of things.

Todd,

Our basement is on the drier side we keep the windows closed and we use a dehumidifier to keep the air dry. If I use unfaced how do you secure it between the studs since there is no paper to staple to the studs? Most unfaced applications I have seen is in attics where the insulation lies horizontal.

Thanks,

Dennis

@ Dennis – The insulation is slightly wider than typical stud bays so friction holds it in place.

Todd,

Thanks for the info on your site about insulating basement walls. It has been very helpful.

I found some information on another site about insulating rim joists, which suggests cutting pieces of 2 inch extruded foam and sealing them in with caulk. I am sealing the joints in the pocket and then sealing the pieces of insulation in. Do you have any suggestions on this topic? I live in upstate NY and I heat my basement with a pellet stove. I have had problems with dampness on the rim joist. I have tried using insulation batts(faced and unfaced, flat and folded), which didn’t work. In your opinion, do you feel that the extruded foam will be effective enough? I am sure that the best solution would be spray foam, but it is very costly.

Thanks,

Jim

@ Jim – I would certainly recommend using foam board on the rim joists. However, I would recommend you seal it in place using foam out of can like Great Stuff.

Todd,

Thanks for the quick reply on my previous post. One more question…would you recommend leaving a gap of about 1/4″ all the way around the foam board and then filling it w/spray foam?

Thanks,

Jim

@ Jim – It certainly is an interesting concept and one that might work well. The problem might be trying to hold the panels in place, foam them and not create a huge mess. We’ve had great luck using tongue & groove foam board and sealing the joints with Tyvek tape.

Todd,

What I plan to do is to cut and glue the foam board pieces to the rim joist with a compatible adhesive. After the adhesive dries, I will then fill the gaps with the foam.

@ Jim – forgive me…forgot you asked about rim joist. You can actually skip the adhesive and use the foam to seal them in place while you hold them. The spray foam holds them well! That’s exactly how we do it.

Todd,

Nice article.

It’s important to note the importance of sealing the seams or condensation will occur. I experienced how much water this actually creates when I put up panels during the winter months as I hadn’t yet sealed/taped the seams.

Could you also add insulation between the joists. If so, should this be faced or unfaced.

Roger

@ Roger – are you asking about insulating between studs or between joists along the rim joist? In either case it’s ok to use either fiberglass or foam. Foam is the preferred solution as it’s much more forgiving when it comes to moisture. Often times we cut foam board to fit between joists and then foam them into place using spray foam from a can (Great Stuff).

Todd,

Thanks for posting the insulation info. I was wondering what your thoughts were, given the following: We moved into a house that has a finished basement; however, with the exception of the rim joist, there is no insulation and no vapor barrier. (Perhaps the prior home owner mistakenly thought it was unnecessary, since the foundation is poured concrete.) While I have yet to see a drop of moisture, I am thinking it would be more comfortable if insulated. We have a drop ceiling, so there is access to the space between the foundation and the drywall. The walls were secured (along with the non-pressurized plate) in front of the space for the french drain (floating floor). What is your recommendation? There is a lot of drywall, so I would rather not have to redo, if possible. Thanks for your anticipated response.

@ Laurence – Obviously your choices are limited if you choose not to remove the drywall. You might be able to use blown in cellulose but we typically install that after a layer of foam board so I’m not sure it’s a great idea. I’m not sure but possibly using spray foam might work but again I have no experience with that. Honestly I think if you want an insulated basement you’re going to have to take down the drywall.

Todd,

Thanks for your response. I was afraid of that. At least I can keep the framing and electrical in place, along with the untreated plate.

Hey todd was wandering how thick of dow board do you use. I was thinking the 2″ stuff but was wandering what you used?

Also nice work on your site!

@ David – Thanks for the compliment. 2″ foam works fantastic. Some folks go with a thinner foam depending on where you’re located. If you can afford the 2″ use it.

Dave, I am insulating my concrete basement wall with 2″ dow foam board, framing with 2×4’s the sheet rocking. My question deals with the floor. I plan to carpet it and was going to use Platon then 1/2″ plywood befor I carpet. With this method how would I deal with the area where the floor and walls meet? Would you recommend running the Platon up the wall a few inches befor installing the foam?

@ Glen – I think that’s a great idea. Does Platon sell some sort of sealing tape? If so I’d make sure that you tape the foam/Platon seam with either their tape or the Tyvek tape depending on which seals better.

Todd,

I have a question. After you glue the rigid insulation boards to the basement wall, frame the wall, then install the insulation batts, do you need a 6mil vapour and any type of vapour barrier over the insulation batts prior to installing drywall?? I’m just a bit confursed. I’ve started insulating my basement with 2″ rigid insulation boards and plan on tuck tapoing all joints. I’ll then frame the walls with 2×4 and installed R14 batt insulation, then i was wondering if i should put a vapor barrier over the batt insulation or not.

Hope you can help me!!

Thanks,

Paul

@ Paul – There are so many different thoughts about vapor barriers in this situation. Me personally I would skip the vapor barrier if you use a min of 2″ of foam and seal the joints.

I leave in Toronto, Ontario, Canada. I have the exact same question as Paul except I have installed 1 1/2″ r7.5 foam with a 2×4 studded wall in front and r14 roxal batt insulation finished with drywall. I am not getting a straight answer with repect to vapour barrier ……… will i need a vapour barrier between the drywall and batt insulation??????

Thanks tonyle1

@ Tonyle1 – Being that far north it’s likely that the 1 1/2″ foam could still be cold on an extremely cold day. This poses a bit of a problem if damp air travels from the conditioned space, through the fiberglass and hits the cold foam surface. Because of that I would use a vapor barrier in your situation.

Todd,

I live in MA and just purchased a home (built in 1953) that has the basement walls already framed up. Currently there are only studded walls with a plastic vapor barrier up against the concrete walls. No insulation no wall surface. There is only about 1/4″ between the studded wall and the concrete wall. Certainly not enough room to slip in a ridgid insulation material. My basement is dry with only the usual summer humidity. What is the correct way to insulate the walls? The last thing I want to have to do in 5 years is tear out molded walls. I will only be using minimal heat there as I will be using it for a wood shop.

I appreciate any help you can provide.

Win the day!

Mike

@ Mike – There are two options.

Option #1 – You could move the walls out away from the concrete far enough to put up foam board. Typically most walls are framed and stood up, then nailed to the concrete and the framing above. If you cut those nails you could move the walls.

Option #2 – If you don’t want to move the walls then I guess I would suggest installing foam board inside the stud cavities. Be sure to seal the studs to the foam board with some “Great Stuff” or something similar.

Best of luck.

Todd,

Thanks for the advice

One more question how do you recommend i install the vapour barrier ……

Do I install a vapour barrier just above foam into rim joist …. sealed with tuct tape to foam [if so what is the preffered type foam vs. typar house wrap vs 6 mil plastic] and then another vapour barrier from floor to rim joist again …. and what is the preferred product.

OR

no vapour barrier at rim joist just above foam but further fill in cavity with batt insulation till it lines up with wall batt insulation. Then vapour barrier floor to ceiling joist with only 1 vapour barrier.

I need to understand the best way to vapour barrier including best product to use given i’m half way done adhereing the 1 1/2 inch foam to my basement walls.

Thanks Todd

@ Tonyle1 – First off be sure you insulate the rim joist with foam board as well. In fact, i would install at least 2 inch thick foam against the rim joist. Be sure to seal the foam to the joists with spray foam from a can (Great Stuff or similar). That way you can end the vapor barrier at the top of the wall framing. Tyvek tape works very well as it adheres to almost anything.

Todd,

Thanks for the help. I would rather not move all the walls. If I follow your instructions will the wall studs be subject to moisture damage or dry rot?

Win the day!

Mike

@ Mike – It’s really hard to say. It really depends on how damp that area will be behind the foam. It’s not a perfect solution but it’s better than using fiberglass. Wish I could say for sure but I just don’t know.

Todd,

sorry for asking so many questions ….. Do you want me to seal the rim joist at the outer most cavity of the wall in line with the foam i just installed ……. i think thats what your recommending

Also, what about the vapour barrier in front of the studded wall …..will it run floor to ceiling including ceiling joist…… if so, am i not trapping air between the foam and batt insulation …… i need to understand the best route for my vapour barrier including the studded wall which will be filled with Roxul R14 [watrer rsistant & fireproof batt insulation]

regards, tony

@ Tonyle1 – No problem on the questions. This stuff is complicated and not easy to describe with words.

I recommend you cut pieces of foam board (2″ min thickness) that will fit between each joist. Install them tight to the rim joist and then seal them with foam along all 4 sides. The vapor barrier should run from the floor up to the top of the framing and then be sealed to the foam on the rim joist as best you can. Try to visualize warm, moist air, traveling until it hits a cool surface. The floor above should NOT be cool so no need to prevent vapor from traveling up. Make sense?

Thanks for all the great suggestions. I have a cinder block foundation. The house was built in the 80’s and though there is no signs of leaking there are some areas where there is some white furry stuff – I think it is called efflorescence. I am planning to go this route.

Clean and Durock the walls, with adhesive install the 2″ dow foam panels,tape them, use 2×4 trek as the bottom plate, and normal 2×4’s for framing. Once framed I was planning on only spray foaming any gaps in joists and around piping. Please tell me know vapor barrier needed…..

I am using 4×8 wood not Sheetrock, for the walls and ceiling. Do you see any corrections.

Also am I better to use a ram set for the trek flooring or drill in mason screws with a hammer drill

Thanks again

James in New Jersey

@ James – Sounds like a good plan! No vapor barrier required. I would use the ramset.

HI,

I am refinishing my basement and have started by attaching 1 inch rigid foam on the foundation walls( i plan then to build at 2 x 4 framing with additional fiberglass insulation). I want to add ridgid insulation to the concrete floor followed by a 3/4 inch tongue and groove osb board fastened to the floor with a ramset.

I have a french cut drain(1 1/2 cut around entire basement floor) and was wondering if i attach the ridgid insulation to the floor butting it to the bottom of the wall insulation and covering the french drain opening and taping where the wall and floor insulation meet would work?

Can I also build my interior wall on top of the 1 inch ridgit insulation i’m putting down on the floor so it will act as a barrier between the bottom plate and the concrete floor?

@ Rich – Lots of folks do their basements just as you propose. I’d be sure to use a sub-floor product like AdvanTech if it were my house.

Would ICF be a better option?

@ Derek – ICF’s are certainly an option with new construction. If the only issue were insulation then I’d say ICF are the best. But they have other issues, how to treat the exterior exposed portion, attachment of materials to the inside and outside, etc. Another product on the market that is making a big impact is a precast concrete panel that has foam insulation cast directly into it. There is a company called Superior Walls that I’m aware of. The product has been used on This Old House and Extreme Home Makeover with success.

Hi

Great article. You reference 2″ foam board in several places. the Dow site only specs out 1″ Super TUFF-R max. Is there another product or am I missing something?

Thanks for the info.

Marc

@ MarcM – Marc it really depends on where you live and what the energy code requires. Here in NH it’s almost impossible to get the basement to pass the code requirement without at least 2″.

I am finishing a very dry basement in Michigan. I am glueing and nailing studs to the poured wall and using 1 – 1/2″ foam between the studs, covering with thick plastic, and drywalling over this. Paneling will then be nailed and glued to the drywall.

Is this an acceptable practice ? Do I need to insulate the walls that I am covering with storage cabinets?

Thank You !

@ Patrick – I would not use your method in a basement. Having the studs in direct contact with the concrete will eventually lead to rot and possibly mold problems. It would be preferable if you install the 1-1/2″ foam first, then attach the studs in front of the foam. I believe it’s always better to insulate a basement and make your home as energy efficient as possible.

todd, thanks for all the insight on this insulation topic. after reading all the comments, my question is why is the batt insulation needed between the studs if the foam board acts as an insulator and vapor barrior? is it only for added r value or is there another reason?

@ Patrick – In many places across the Country energy codes have now been passed which specify minimum insulation values within the homes envelope based very complicated models including window/door areas, heating systems, geographical location, etc. Using a combination of foam board and fiberglass is one approach that limits the cost while benefiting from an approach that works. As with any issue there are many solutions to consider.

Have you seen any basements where the floor is done similar to the wall insulation you’ve described. 2″ foam board, seams taped and spray expanding foam into gaps between floor and wall insulation. Cover the boards with plywood. Then you can do your walls and they are protected from the damp floor bt the foam board. You can then put any flooring at all.

@ Chris – I have seen this done. Typically people end up using tapcon screws to secure the plywood to the concrete.

Great article Todd! I do have a questions for you though. I live in a 4 year old home with a walkout basement (in minnesota). I’ve recently been pondering to finish the basement, but when I was drawing it out and started looking closely at the walls, there are dime to half dollars spots of mold behind the plastic / infront of the paperless fiberglass insulation. The mold spots are in random locations, about 4 feet in frequecy. They are high and low, and have little to no rhyme or reason to where they are located.

To my inspection, the plastic was put up as “air tight” as possible. They taped and caulked all seams (is that normal?) We have never had water damage and it’s never seemed damp or moist. They did not use any foam board. I guess my question would be… do I start over? Should I tare everything out and redo it? also, any thoughts or comments on what they did wrong?

For the mean time, I’ve been contemplating perforating the plastic and opening up the air vent (there is only one) all the way to get air moving. Would that help or hurt?

Any feedback would be greatly appreciated. Thanks!

@ Greg – Can you be more specific where the mold is occurring? Exterior framed walk-out walls? Concrete walls with insulation?

@ Todd – after looking at it a little closer, there is only mold on exterior framed walls, not where the concrete is. So the entire west side wall, and mid/upper portions of the north and south have mold (all above grade). From what I can tell, the East side has no mold.

@ Greg – Your situation is fairly common with walk-out basement walls above grade. It’s hard to say what has caused the problem but I’d have to guess it’s caused by excess moisture in the wood framing when the house was new, trapped between the vapor barrier and exterior sheathing. If it were my house I’d remove that insulation, let things dry out, remove the mold and start over after it dries really well. You might want to wait till summer.

Thanks Todd. would you switch to foam or stay with fiberglass?

@ Greg – Do you walk out walls have Tyvek or similar on them? Are you controlling humidity in your basement? You should be able to use fiberglass on the wood framed walls if you get the moisture under control. Definitely foam for the concrete walls.

@ Todd – Yep, we have some brand of house wrap; not sure it’s tyvek. We have a humidifier added onto the furnace, but we do not have a dehumidifier, so I guess the answer is no.

Todd,