How To Insulate A Concrete Floor

Insulating Concrete Floors

Methods To Insulate A Concrete Floor

There are numerous methods for insulating concrete floors and slabs. The method that you chose really depends on cost and available headroom. If you’re finishing a basement most building codes require a minimum finished head room of 7′-6″. So any choice in the insulated sub-floor must account for that minimum height including the finished ceiling construction. The following are two methods that we’ve used in the past with great success.

Insulated Sub-Floor Panels

There are numerous products being sold today that are typically a combination of rigid foam insulation and some type of sub-floor material like OSB. There are quite a few of them on the market including Barricade Subfloor Tiles. The subfloor tiles are really great for folks with little DIY experience and clearance issues as they provide one of the thinnest insulated options.

Insulated Sub-Floor

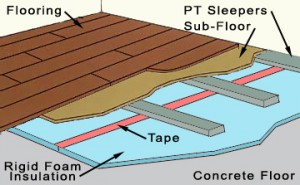

If you’ve got adequate headroom and few interferences then this is the method that we like best. This method works great if you don’t have many doors and you can deal with the higher sub-floor at the stairs. The method is quite simple consisting of a layer of foam board insulation, sleepers and a plywood sub-floor (see diagram above).

- First you need to be sure the floor is clean. Be sure to fix any problems in the concrete floor such as cracks, spalls and water problems.

- Install a layer of rigid foam board insulation such as Styrofoam Tongue and Groove or Styrofoam Brand Highload 40 (depending on the loads you have the first one provides 25 psi and the second one provides 40 psi). We recommend at least 1 inch of foam board. Use a good quality foam board adhesive to adhere the foam to the concrete. If you’re interested in learning more about foam board insulating properties then check out our article on R Values Of Foam Board Insulation.

- Seal all the seams of the foam board insulation. We recommend you tape the seams with Tyvek (or similar) tape. You can seal along the walls with spray foam from a can (Great Stuff or similar).

- Install pressure treated sleepers. We recommend using 3/4″ thick pressure treated decking. Use foam board adhesive along the bottom of the sleepers and also attach the sleepers to the concrete using masonry nails or a powder actuated nailer.

- Install a layer of 3/4 inch tongue and groove AdvanTech (or other sub-floor material). We recommend you screw the sub-floor to the sleepers using stainless steel screws and sub-floor adhesive as well. We really recommend you consider using AdvanTech because of it’s excellent properties in damp environments.

- Finally install your finish flooring. You can install any type of flooring at this point because of the sturdy sub-floor.

Final Thoughts On Insulating A Concrete Floor

The only issue to watch out for in this situation is the height. You’ll most likely end up with 1 inch of foam board, 3/4 of an inch sleepers and 3/4 of an inch for the sub-floor for a total of 2-1/2 inches. This will most likely require doors to be lifted and stairs to be reconfigured. However, you’ll have a very warm comfortable floor and a whole lot less moisture in your basement.

Want To Hire A Professional?

If you’re feeling a bit overwhelmed by a full basement remodel then you may want to consider hiring a contractor. A good place to start is using industry proven contractor referral companies. Company like ServiceMagic offer a great referral service. Just follow the next link:

Recent Posts

Framing Stick Nailer vs Coil Nailer

Which is Better a Stick Nailer or Coil Nailer? Framers have many choices in nailers…

How Many Roofing Nails Per Square of Shingles

Estimating How Many Nails for a New Roof When it comes to estimating materials for…

Composite / PVC Decking – Layout Tips & Advice

Composite / PVC Decking Layout Tips and Advice Composite and PVC decking have really changed…

Benefits of an ERV System (Energy Recovery Ventilator)

Benefits of ERV Systems (Energy Recovery Ventilator) If you're building a new home or doing…

Vermiculite Attic Insulation Abatement

Vermiculite Attic Insulation If your home was built before 1990 there is a chance it…

Nuisance Tripping of AFCI (Arc Fault) Circuit Breakers

Arc Fault (AFCI) Circuit Breakers Tripping Often An arc-fault circuit interrupter (AFCI) or arc-fault detection…

View Comments

Todd,

Great articles!

Couple questions for you as i'm thinking of laying carpet in my basement (there's existing tile) but want an insulated floor:

1) I assume you recommend removing the tile first?

2) What is the downside of using 1/2" or 3/4" XPS instead of 1"? Any water vapor issues in that case?

3) Are the PT sleepers truly needed? Couldn't I just tapcon/powder nail OSB or Plywood into the concrete directly through the XPS? Or are there concerns with water vapor having direct contact with the subfloor in that case?

4) Could I use 1/2" OSB instead of a 3/4" subfloor? Any weight concerns....not putting a pool table down there...heaviest thing would be an elliptical.

Just a little concerned with height (will need to cut bi-fold doors down), but still want to get decent insulation to have a warm floor.

Thanks for any feedback!

@ Mike - Thanks for the compliments.

1. If you're worried about height than removing the tile will help. I'm not sure it's absolutely necessary to remove it.

2. The only downside is less insulation value and less protection from moisture. I think you might consider a layer of poly under the foam if you go thinner.

3. The Sleepers are not necessarily needed. We've actually done it both ways. When you use sleepers it seems to work better connecting them to the floor then screwing the plywood down.

4. 1/2" will work if you don't have sleepers.

Hope this helps.

Todd, I enjoyed your article on insulating basement walls. In fact, I began my basement bathroom project, and will use your methods in addressing the concrete walls around the perimeter of the basement. Should be more than enough to handle Iowa's winters.

I don't quite understand how foam board has a low enough compression factor that will support furniture, etc. So am I to assume the subfloor above the foam board will take care of spreading the load across the foamboard? And any thoughts otther than price considerations for using composite decking material as sleepers?

Thank again.

@ Joe - Thanks for your compliment.

Foam board (blue board, pink board) actually have a fairly high compressive strength when they are sandwiched between two products such as the concrete below and plywood above. We've done this method several times and it works very well. Hadn't really given much thought to using composite decking. I suppose that would work out pretty well aside from the price. Good luck!

Todd, thanks for the great website and information. My question is similar to the one you addressed here. I was planning on using 1" T & G Pink Board on my basement floor and then putting 3/4" T & G OSB on top of it and then using tapcons to screw it all directly into the concrete. I was then going to use 1 1/2" foam board on the concrete walls and build my 2 x 4 walls with batt insulation inside the foam board on the walls and on top of the T & G OSB. However, my father in law is questioning whether the foam board on the floor can withstand the weight of the walls and OSB on top of it without getting crushed or being unstable. There will be a bedroom, family room and bathroom in the basement with typical items for these rooms (bed, dresser, couch, televsion, tub, toilet, vanity, ect) but nothing with excessive weight (pool table, ect). Are my father in laws concerns valid or will this set up be able to handle the weight? He advised using a joist system with treated lumber on the floor with the Pink board insulation between the joists.

Chris - This system is used all the time. If you look at the rated pressure for foam board insulation and you compare to code floor loading it works fine. In some cases with extra loading (pool table for example) you can purchase the stronger version but for typical room it's not necessary. I'd do it in my own home.

Good luck.

Foam is used under your roads especially near bridges. If it can support tractor trailers I think you'll be fine. Just be sure you use a dense foam.

Todd,since I do have an issue with height,could i use 1/2 inch foam & put a laminate floor on top,water is not a problem.Thanks for the help.

@ MikeR - What would actually hold down the foam? I'm just not sure it would be a very good system without some mechanism holding everything in place.

Todd,

Have some follow up questions for you :)

In looking at the XPS panels available to me at local stores, I saw Owens Corning Foamular 150 and 250 (high density). Noticed that the only difference is the compressive resistance of the 150 is 15psi and the 250 is 25psi. I don't think they carry the 250 in 1" size (or at least not in stock....however they do have 3/4" 250 in stock). Which type do you guys use? Do you think the 150 is sufficient? Like another commenter, I assume the plywood/OSB distributes the load over the panel.

Also, if I didn't use sleepers, and didn't use AdvanTech, in general do you recommend plywood or OSB? I've seen 3/4" T&G OSB be recommended...also have seen 3/4" T&G Sturdi-floor plywood for ~$17. I had wanted to use 1/2" to save height and 1/2" square edge OSB panels are extremely cheap, but aren't T&G. In such a setup is T&G a necessity? I assume it would cut down on the number of Tapcons needed?

Finally, if I leave my tile down and put the XPS panels over top, do you think there are any issues with the small air gaps caused by the grout lines? I had read the XPS should be tight against the wall/floor, but also have seen other products that market an air gap as a benefit...

Any recommendations either way? As you can see I analyze everything for better or worse.

Thanks again!

Mike

@ Mike - I don't think there's much difference between the 150 and 250 for your application. I do think you should stick to T&G as it really stiffens the floor. I also think you really should have 3/4 inch plywood over foam board. I also don't think the gaps along the grout lines are a big issue.

I have a question regarding insulating a poured slab cellar floor with Barricade. According to instructions, an expansion space should be left around outside edges, but doesn't leaving this gap create a non vapor barrier? I thought that in order to prevent moisture from the meeting of cold and warm air, you need to have any gaps sealed. I plan on using 1 1/2" rigid foam panels on the walls before framing, but still am up in the air as to how to insulate the cellar floor. Height clearance is an issue, and I would like to be able to put down carpet. I live in the Western New York area where our winters are cold.

@ Betty - The floor guys don't care much about the wall issues! Obviously there is no perfect solution. I would install the Barricade system first, leave the gap at the concrete. Then bring the 1-1/2" foam down on top of the barricade.

Todd -- great site. I am redoing my basement, ripping out hte old wall frames and fiberglass batts. There is an existing slab floor. Following your recommended methods for insulating floors and walls, should I insulate and put in the walls first, or the subfloor first? Also, did you see the article in Fine Homebuilding September 2009 about subflooring -- any comments? Finally, if the basement will be heated and I use a suspended ceiling, do you think I need to install fiberglass insulation between the main floor joists? Thanks so much, Mike

@ Mike - Thanks for the compliment. I would insulate the floor first if you have the luxury to do so. I did not see the article, can you share the basic information and what your question is? No need to insulate the ceiling above unless you're worried about getting too much heat above.

Todd -- Scanned in teh FH article, but see no way to attach it to the comments. Essentially, the author recommends that when finishing a basement, adhere to the following method for the floor:

1. Install a class-I vapor retarder, specifically a 10-mil to 15-mil polyethelene sheet, taping all overlaps.

2. Install a floating subfloor using two layers of 1/2 -nch plywood. Glue or nail the second layer to the first layer, but do not penetrate the vapor barrier.

3. Use high-quality engineered wood flooring to finish.

Following up on my initial "wall or floor first" question, would the wall framing go right on top of the subfloor?

Thanks again,

Mike

Mike - You are correct, place the wall on top of the sub-floor.

How would you address sloping floors using this subfloor method? In my basement, the concrete floor slopes towards the outer walls and then towards a drain. Would shimming betwee the sleepers and the subfloor be an option, or might this create uneven load distribution on the XPS? Would something like Dricore panels be better in this situation (aside from cost and height differences)?

@ Jeffrey - This method could still work if you can manage to cut good tapered sleepers (this might be really hard to do). Does it slope much?

Hey Todd-

Thanks for the reply. Unfortunately I think it's going to be too much for tapered shims, especially since there is a ridge more or less in the middle. The house is almost 100 years old, and it looks like the floor is designed to channel water in either direction away from the middle. Between that and the relatively low ceilings to begin with, I think I might be stuck with one of the dimpled plastic membranes and carpet on top of that. I'm not crazy about putting carpet in the basement, but I'm not confident that I can get the floor level/flat enough for tile or laminate while leaving suitable headroom.

Any suggestions?

@ Jeffrey - Short of tearing up the slab I don't really have any ideas. Are you sure that you've got no water problems? Be darn sure before you install carpet.

How many tapcon screws would you recommend to hold down a 3/4" subfloor over 1" XPS foam?

@ Jody - It really depends on how flat the floor sits. First off I would recommend using 3/4" tongue and groove AdvanTech sheathing. It will likely require 4 to 6 screws per sheet.

Follow up question,

I am using 1 inch foam with 23/32 T&G advantec board for my subfloor.

You recommended using 4-6 screws per Advantec board. Since it is a T&G, this means that screws need to put pn the edges or you need to put tapcons all around each board.

Please advise.

Thanks,

Tariq

Tariq - The number of screws really depends on how flat the floor sits. There's no structural reason to use them. It's really just a way of keeping the floor nice and tight to the concrete. You'll need to adjust accordingly.

i am using 3/4 tongue and groove plywood (not advantech). at this point the wood seems pretty flat :)

I will try to use 6 per sheet.

Thank you.