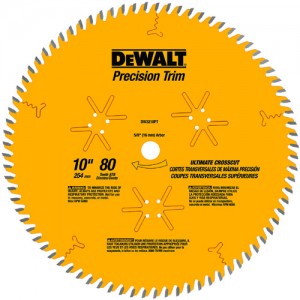

DeWALT Precision Trim Saw Blades Review

Precision Trim Saw Blades

Design Features

DeWALT has obviously invested some time and money into designing these new Precision Trim saw blades. Some of the these features include:

- Laser Cut Expansion and Body Slots – The laser cut slots help reduce harmonic vibration and blade flex resulting in more accurate cuts.

- CNC Ground Teeth – CNC grinding creates ultra-sharp teeth and optimized grind angles resulting in cleaner cuts and reduced tear out problems.

- Tough Coat – The blades are coated with the Tough Coat anti-stick coating that helps prevent friction, heat and load on tools.

Precision Trim Saw Blade Review

We tested the Ultra-Fine Finish and the Smooth Crosscutting blades on a sliding compound miter saw and we tested the Combination blade in our Contractor tablesaw. We used some birch cabinet molding for our tests on the miter saw and some MDO plywood on the table saw.

Accuracy

Cuts with Less Force

One of the things we noticed was how easy these blades cut. The manufacturer points out several features that should reduced the required force necessary to cut and we think they are on to something. It’s hard to tell which features truly account for this but it’s certainly a benefit.

Tear-Out

Overall Impression

The new line of DeWALT Precision Trim saw blades is great for carpenters that work on finish work and need to rely on a well built affordable precision blade. These blades offer all the features of some of the new high end finish blades that are on the market at a substantially lower price point. The blades are accurate and have large C4 Carbide teeth that can be sharpened several times for long life.

If we had to offer one bit of criticism it would be the smoothness of the cut below the face through the wood thickness. If you notice in the photo above the cut did have some roughness along the circular blades path. However, this is just a small criticism and our overall impression was very favorable.

If you’re looking for a quality finish saw blade at a very reasonable price then we think you should consider the new DeWALT Precision Trim saw blades.

Where To Buy Precision Trim Blades

The new DeWALT Precision Trim Saw Blades are now available across the Country at the Big Box stores, hardware stores and lumber yards. If you’re interested in purchases one of these new blades online you can pick up on of the blades we tested at the following links:

- DeWalt DW3218PT 10-Inch 80 Tooth ATB Crosscutting Saw Blade with 5/8-Inch Arbor and Tough Coat Finish

- Click Here to Buy DeWalt DW3215PT from ToolKing.com

- DeWalt DW7150PT 10-Inch 50 Tooth ATB Combination Saw Blade with 5/8-Inch Arbor and Tough Coat Finish

Recent Posts

Framing Stick Nailer vs Coil Nailer

Which is Better a Stick Nailer or Coil Nailer? Framers have many choices in nailers…

How Many Roofing Nails Per Square of Shingles

Estimating How Many Nails for a New Roof When it comes to estimating materials for…

Composite / PVC Decking – Layout Tips & Advice

Composite / PVC Decking Layout Tips and Advice Composite and PVC decking have really changed…

Benefits of an ERV System (Energy Recovery Ventilator)

Benefits of ERV Systems (Energy Recovery Ventilator) If you're building a new home or doing…

Vermiculite Attic Insulation Abatement

Vermiculite Attic Insulation If your home was built before 1990 there is a chance it…

Nuisance Tripping of AFCI (Arc Fault) Circuit Breakers

Arc Fault (AFCI) Circuit Breakers Tripping Often An arc-fault circuit interrupter (AFCI) or arc-fault detection…

View Comments

Too many times have I seen carpenters using 24 tooth blades to do trim work! I personally like the DeWalt saw blades and use them regularly...

@ Keith - They do make good blades, the non-stick coating on their blades does a great job keeping the blades from binding.