Basement Insulation Detail

Basement Wall Insulation Detail

Basement Wall Insulation

Lately I’ve been swamped with questions about insulating basement walls properly. So I’ve written this article to share with you a Basement Insulation detail that I hope will clarify some issues.

Basement Wall Insulation Detail

Moisture Problems

Before you choose an insulation method for your basement it’s important to understand the moisture problems associated with basements. Whether your foundation walls are concrete or masonry the moisture problems are really the same.

Concrete and masonry walls have a significant amount of moisture (water) contained within the material. The moisture will be present in the foundation materials for years and will never fully dry out. The foundation wall will go through drying cycles over time. The upper portion of the wall will dry to the outside and inside while the lower portion will dry to the inside of the house.

The drying cycle releases moisture which can get trapped in adjacent materials causing moisture problems such as mold, mildew and rotting. Knowing that this cycle will continue year after year it’s important to choose an insulation detail that prevents that drying moisture from entering vulnerable materials such as wood framing, fiberglass insulation, drywall and other moisture sensitive materials.

We also need to prevent water vapor from the finished space from coming in contact with the cold foundation walls and forming condensation. Unlike traditional walls where we have vapor barriers on the outside and inside foundation walls present some challenges. In the proposed basement wall insulation detail we’ll provide a moisture/insulation barrier along the face of the foundation wall and then a vapor barrier on the warm side of the framing of the basement walls.

Insulation Detail – Insulating Basement Walls

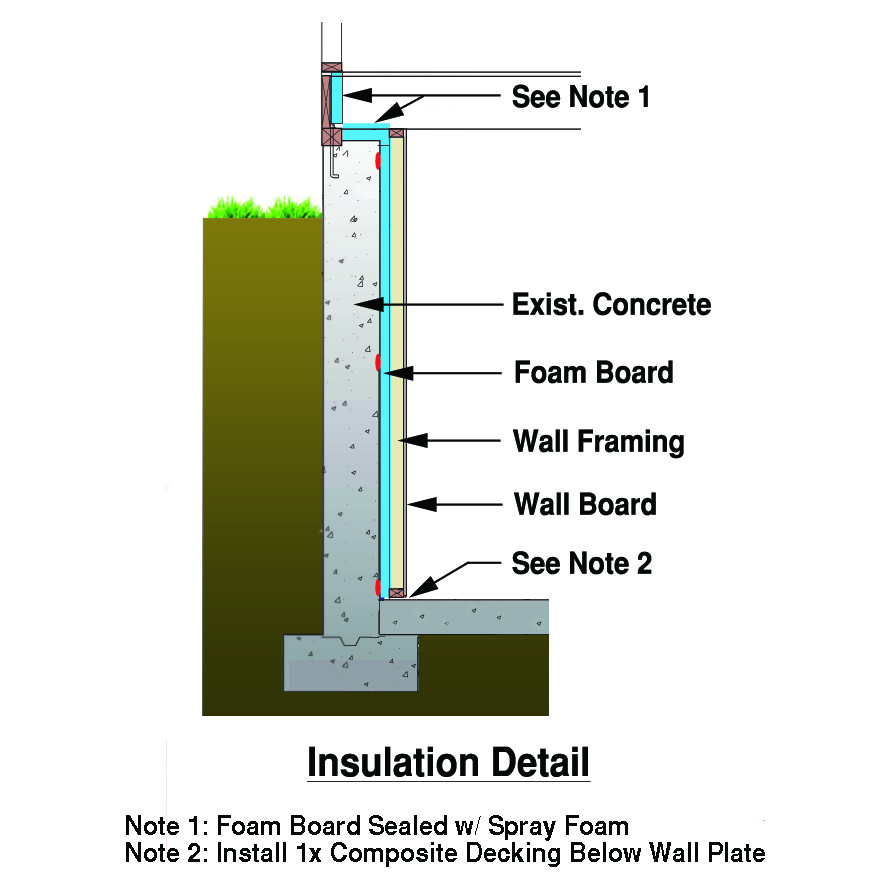

The insulation detail shown in the figure is a detail that I’ve used several times with great success. This detail is my preferred method for insulating basement walls short of having the walls sprayed with foam. There are several variations of this detail that can be used to achieve the same result.

- Install rigid expanded polystyrene insulation from the slab up to the top of concrete (masonry) wall. Install the same insulation along the top of the exposed foundation wall and then up along the rim joist to the bottom of the sub-floor.

- The vertical expanded polystyrene insulation can be attached to the wall with a multi-purpose adhesive designed for foam. The top portions along the top of wall and rim joist can be installed using spray foam such as “Great Stuff”.

- Be sure to seal ALL the joints in the foam with tape. The best tape I’ve found for adhering to foam board is Tyvek tape.

- Frame a wall in front of the expanded polystyrene insulation. The wall can be as simple as strapping shot through the foam into the concrete or a traditional framed wall. If you frame a wall I recommend you install a piece of 1x composite decking below the bottom plate. This will prevent moisture from wicking up into the framing and finished wall.

- Optional – Install insulation in the stud cavities. Depending on the thickness of the foam you can save some money and supplement insulation in the stud cavities, it’s fine to use fiberglass or cellulose in this step. See Insulating A Basement with Cellulose and Basement Storage Room for more details.

- Install a vapor barrier. Either use faced insulation in the wall cavity or install a vapor barrier (if you use Spray-In-Place Cellulose Insulation you may omit the vapor barrier).

- Be sure to leave a minimum 1/2″ gap between the slab and finished wall board.

Once you’ve effectively sealed off the drying cycle from entering the house side the drying cycle will have to happen to the portion of the wall above grade on the outside. As i said there are several alternative approaches to this method that will work. The key is to cut off drying moisture from the foundation wall and prevent it from entering the finished wall cavity.

Recent Posts

Framing Stick Nailer vs Coil Nailer

Which is Better a Stick Nailer or Coil Nailer? Framers have many choices in nailers…

How Many Roofing Nails Per Square of Shingles

Estimating How Many Nails for a New Roof When it comes to estimating materials for…

Composite / PVC Decking – Layout Tips & Advice

Composite / PVC Decking Layout Tips and Advice Composite and PVC decking have really changed…

Benefits of an ERV System (Energy Recovery Ventilator)

Benefits of ERV Systems (Energy Recovery Ventilator) If you're building a new home or doing…

Vermiculite Attic Insulation Abatement

Vermiculite Attic Insulation If your home was built before 1990 there is a chance it…

Nuisance Tripping of AFCI (Arc Fault) Circuit Breakers

Arc Fault (AFCI) Circuit Breakers Tripping Often An arc-fault circuit interrupter (AFCI) or arc-fault detection…

View Comments

When you put the foam up against the concrete wall, where does the moisture go then? Wouldn't it get trapped in the tiny space between the foam and the concrete? I am going to be finishing my basement in a year or two and the old (1928) walls do sweat quite a bit and I don't want to get a layer of mold growing between the foam and the cement.

Thanks!

The whole process is quite complicated. However, by sealing the inside you force the moisture/drying to occur out the top of the wall on the outside of the house where the concrete is exposed to the outside air.

Secondly, mold will only grow in a place that has moisture, air and a food source. Mold likes things such as wood, paper, fiberglass, drywall, etc.

Would it then be wise, in the winter months, to keep snow away from the exterior exposed concrete?

Also, a bit more unrelated to insulation; I am most likely going to use Delta-FL (or a similar product) on my slab before carpeting. Would you recommend building the walls on top of the material, or install the material after building the walls?

Thanks again!

Actually snow is an amazing insulator if you can believe it. Snow up against a foundation will certainly help insulate it. Unfortunately, when spring comes that water can be an issue.

I'm not familiar with Delta-FL, however, I wouldn't install that under the walls. I'd install a piece of composite decking under the bottom plate and install the sub-floor up to the wall.

What size of the composite decking would you install under the bottom

Plate?

The width of the framing.

Very helpful, Todd. Thanks.

I have a step-son living in my 58 year old basement (tenporarily) and the area was cold. I saw your article about insulating basement walls and really picked up on it. I used 1" DOW blueboard and used only 8 pieces around a corner during the winter. When spring comes I will complete the project with continued styrofoam and stud wall contruction. It has been absoulutely amazing the difference in that corner of the basement. I have no moisture problem but the difference in wall temperature is about 30 degrees between styrofoam and naked wall. I can see this is a very good way to take care of the coldness of a basement. Thanks for the info. Sincerely Mikey in MO.

@ Mikey - Glad it's working out for you. Be careful with bedrooms in basements. Be sure you have proper egress for emergency escape. Each year there are tragic deaths for people living in basements that get trapped in a fire.

shouldnt he have used open cell white styrofoam instead of closed cell blue board

No way! Open cell foam insulation is a disaster in basements and any place that is prone to moisture problems. Frankly I'd NEVER put open cell in any house. The only people using it are folks trying to cut costs.

I am thinking of using 4X8X1" sheets of insulation and just covering the top 4' of the wall. My thought is that the wall would be covered to bottom of frost line. Will this work? I would then fill in between the joists with blanket insulation.

@ Ken - The problem with that is the lower half of the wall will still be very cold and very damp. The blanket insulation will then collect moisture and it won't be long before mold starts. Sorry to say but you really need to insulate the full height of that wall with foam.

Todd, Good easy to follow info. I have 8"x9' poured walls. The cavity between the floor joists (lengthwise) and the outside wall on the sill plate of the house is very restricted, making it almost impossible to insert insulation board in that cavity. I intend on using 4'x8'x2" sheets of Extruded Polystyrene Insulation. I have planned on attaching the sheets of insulation so they are even with the top of the concrete wall, leaving the wall below the sheet to the floor (approx. 1') uninsulated. I would then have a contractor spray foam the sill plate cavities overlaping the sheets of polystyrene already attached to the walls. Is this a viable option? If it is can you identify some pro's, con's and concerns. Thanks.

@ Chuck - Sounds like a great plan. I do have one question though, why are you leaving the bottom 1' open? Why not cut a piece to fit that as well and seal the seams? Are you planning on finishing the basement?

Todd, Thanks. I was unsure if the benefit from adding insulation at that depth would justify the additional expense. If so, it may be as well to attach the sheets from the floor up and then have the contractor spray from the rim joist cavities down the extra foot or so overlaping the sheets of polystyrene at that point. How much foam would you suggest in the rim joists and sill plate area? I plan on 2'x4' walls with 1/2" mold and mildew resistant drywall (Paperless ?) all the way around. I was going to leave about a 1 1/2" airgap between the polystyrene and the wall without additional insulation. I used the Zip Code Insulation Program Worksheet you suggested (www.ornl.gov/~roofs/Zip/ZipHome.html) and I think that with the airgap I get the R-11 the Program recommends. The addition of wet cellulose spray insulation in the 2"x4" walls maybe overkill since I'm using the 2" sheets of Extruded Polystyrene. If I'm unhappy with the results, can I blow in cellulose from the top later without increasing the concern of mold or mildew? Thanks again.

@ Chuck - I think you've got a great plan. 2" of foam board will do a great job and I think it will work well. You can always install cellulose later and it comes with a mold inhibitor in it.

Todd, Thanks for your comments. Is there a particular brand adhesive you recommend? How much adhesive do I need to use per sheet? Is there a pattern you suggest? How many sheets will one tube of adhesive cover? Thanks.

@ Chuck - Most hardware stores carry an adhesive (in a tube similar to caulking) that's rated for foam board. Be sure to read the label and find one that's made for foam. There's no special way to do this and it really doesn't take much. However, you'll probably have to temporarily prop something up against the foam until the adhesive cures. Once it's cured it typically works very well.