Wood Shop Dust Collection

Dust Collection

Dust collection is an essential part of any shop. It keeps us from breathing in harmful dust particles and it helps keep our shops clean. Dust collection systems can range from a simple inexpensive shop vacuum to huge expensive systems that require an entire building!

This section of the site will offer up information about my dust collection system along with resources that you might find helpful for your shop. Please feel free to ask questions and leave suggestions.

My Workshop Dust Collection System

My shop is fairly representative of a medium size shop. The shop will have all the essential pieces of equipment including: Cabinet Saw, Miter Saw, Band Saw, Planer, Jointer, Sanding Station and a Drill Press. All of these can benefit from Dust Collection so the shop is set up to accommodate all of these items.

My shop is fairly representative of a medium size shop. The shop will have all the essential pieces of equipment including: Cabinet Saw, Miter Saw, Band Saw, Planer, Jointer, Sanding Station and a Drill Press. All of these can benefit from Dust Collection so the shop is set up to accommodate all of these items.

Dust Collector

The heart of my system is Delta’s Model 50-763, 3 HP Motor Dust Collector running at 2700 CFM. This large dust collector is set up below my shop in the garage in a corner away from the main house.

Delta 50-763 Product Review: If you’d like to read my thoughts on this dust collector please check out this article: Delta 50-763 Product Review

From it’s location in the garage I’ve built a 6″ round duct up to the shop. The 6″ main trunk starts off at the dust collector with 6″ flexible hose (this prevents vibration from getting to the solid trunk and also allows me to move the unit to clean behind it) and connects to a 6″ PVC trunk line.

The 6″ PVC (SDR35) trunk line runs to 3 locations including: left side of shop, right side of shop, and down under the center of the shop to the cabinet saw. I’ll be writing more detailed articles on how I built the duct work along with information on static charge dangers.

From the trunk lines I have runs of 4″ (Sewer and Drain) PVC running behind the walls which serve each of the workstation locations. Each of the 4″ line outlets is capped with a 4″ metal blast gate.

From the blast gates I use 4″ clear flexible hose connected to the machines.

I’ve created some interesting dust collection details at the Miter Saw Station which I’ll also provide articles on.

- Flexible 6″ Hose up to Main Duct

- 6″ Diameter Main Trunk Lines

- Three Branches, one down each side of shop and one in the middle for the table saw.

- Custom reducer that the local school welding class made for me.

- Dust ports popping through from space behind finished walls.

- Branch duct running behind walls.

- Each outlet has a blast gate.

- Standard pipe hangers were used to hold it in place.

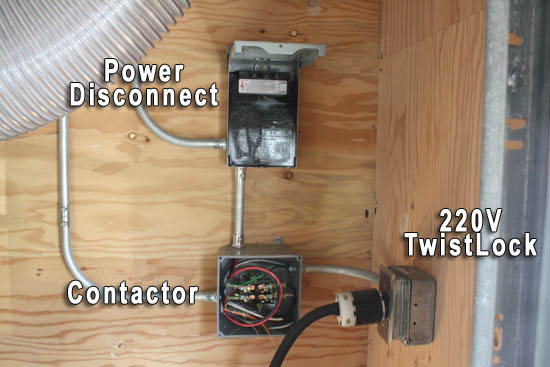

Remote Switching of Dust Collector

Seeing that my dust collector is located in the garage down below the shop I needed an easy way to turn it on and off from upstairs. Working with my electrician we developed a system that allows me to turn on and off the dust collector from many different locations in the shop. I have a switch located at each piece of equipment that allows me to turn on or off the dust system. If you’d like to learn how we did this check out the article: How To Remotely Switch A Dust Collector

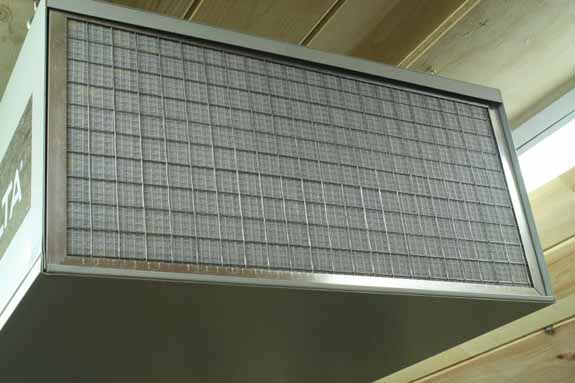

Fine Dust Cleaner

Another important feature in my shop is the Delta Ambient Air Cleaner. Fine dust particles are one of the more serious health concerns in a shop. With this device I can clean the air of particles down to 1 micron in size.

Another important feature in my shop is the Delta Ambient Air Cleaner. Fine dust particles are one of the more serious health concerns in a shop. With this device I can clean the air of particles down to 1 micron in size.

I have this mounted in the center of the shop hanging from the ceiling.

I control it with a remote control that comes with the unit. It has 3 speeds and a two stage filter system. The outer filter collects dust particles 5 microns in size and larger. Smaller particles that pass the first filter enter an internal filter that removes particles from 1 micron up to 5 microns.

You can read a full review of it here: Delta Air Cleaner Review. Or check out the short video below for my thoughts on this air cleaner.

More Pictures of the Delta 50-875 Air Purifier

Front Cover Including Controls and Air Intake

Air Flow Meter – Indicates when Filters Should Be Changed

Rear Panel – First Stage Removable Filter

Rear – 1st Stage Filter Removed Showing Fine Particle Filter Bags

Remote Control